RouteMaintenance Software

Innovative and adaptable fixed plant maintenance software

A Simple Repeatable Process

Is your team swamped in paper-based work orders and instruction material?

Or do you have a workforce with varying levels of experience or plant knowledge?

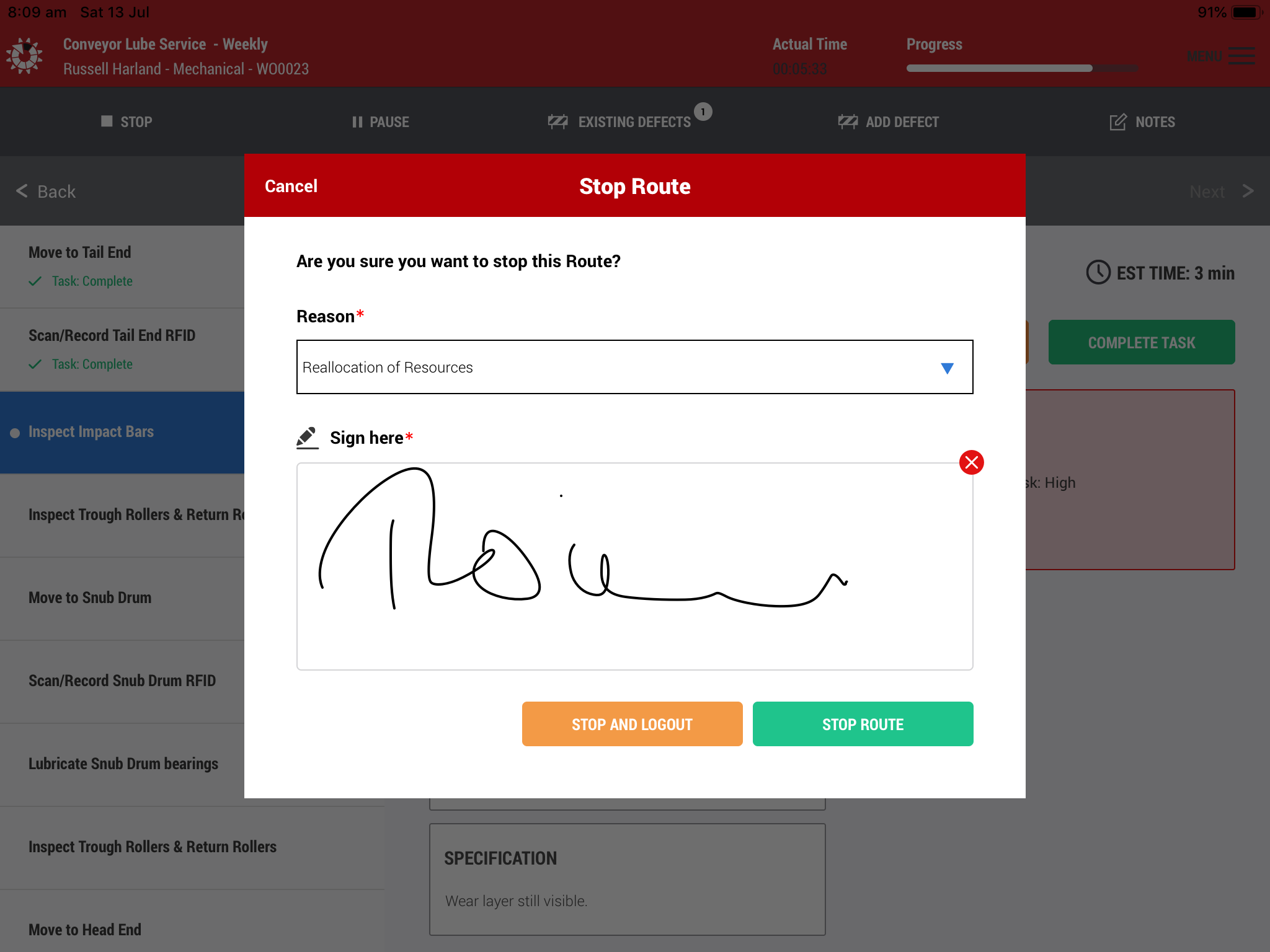

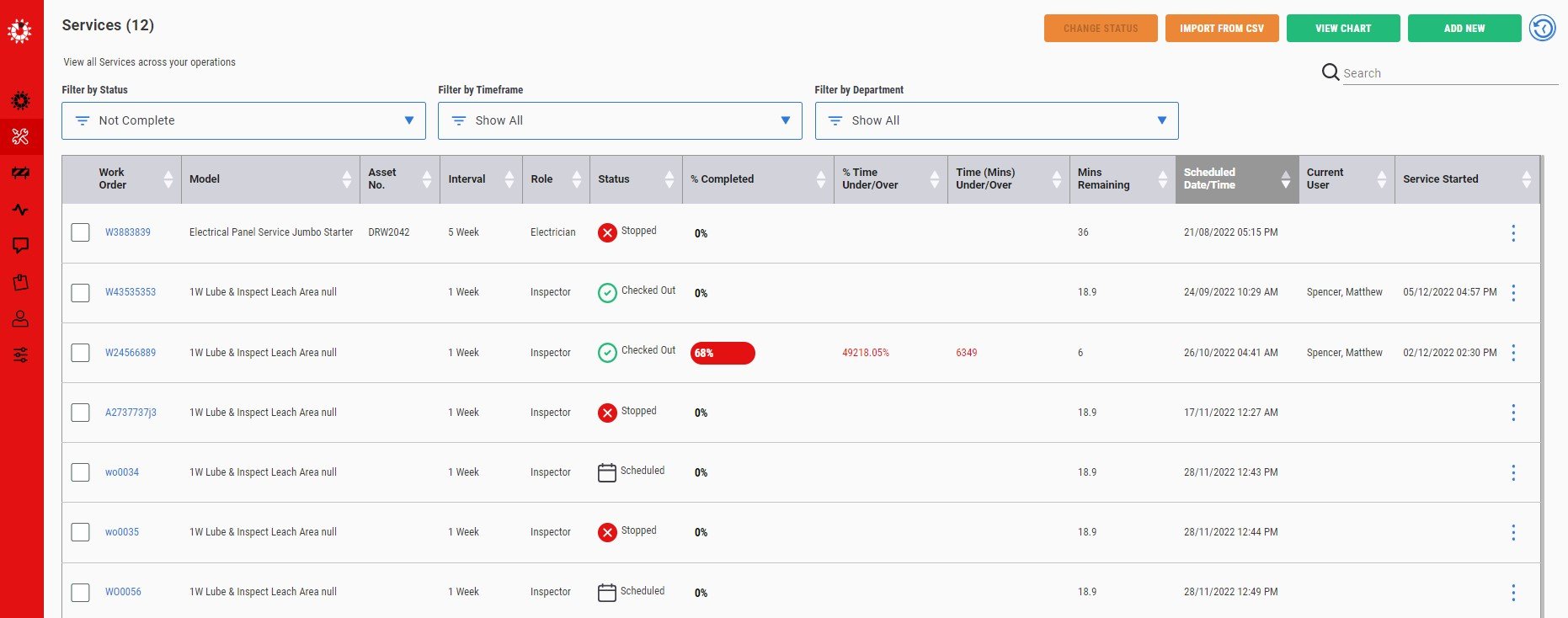

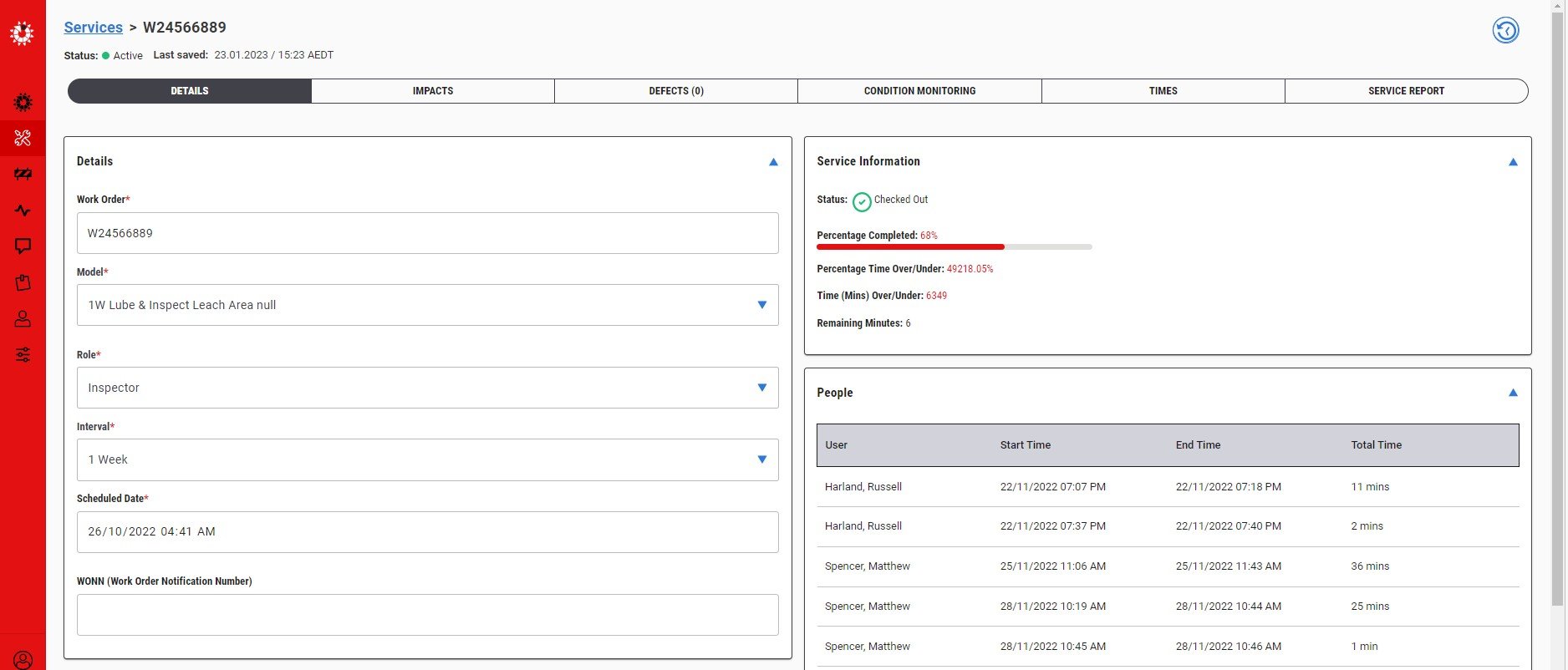

RouteMaintenance electronically sets out for a technician what needs to be done, when, and how. It also details what’s required in the way of tools, lubricant, parts, and permits, so nothing is missed.

Images, videos and PDFs can also be used to support the steps of each task. And the system clearly identifies any risks involved and when contamination control needs to be applied.

But we take it further than just digital instructions

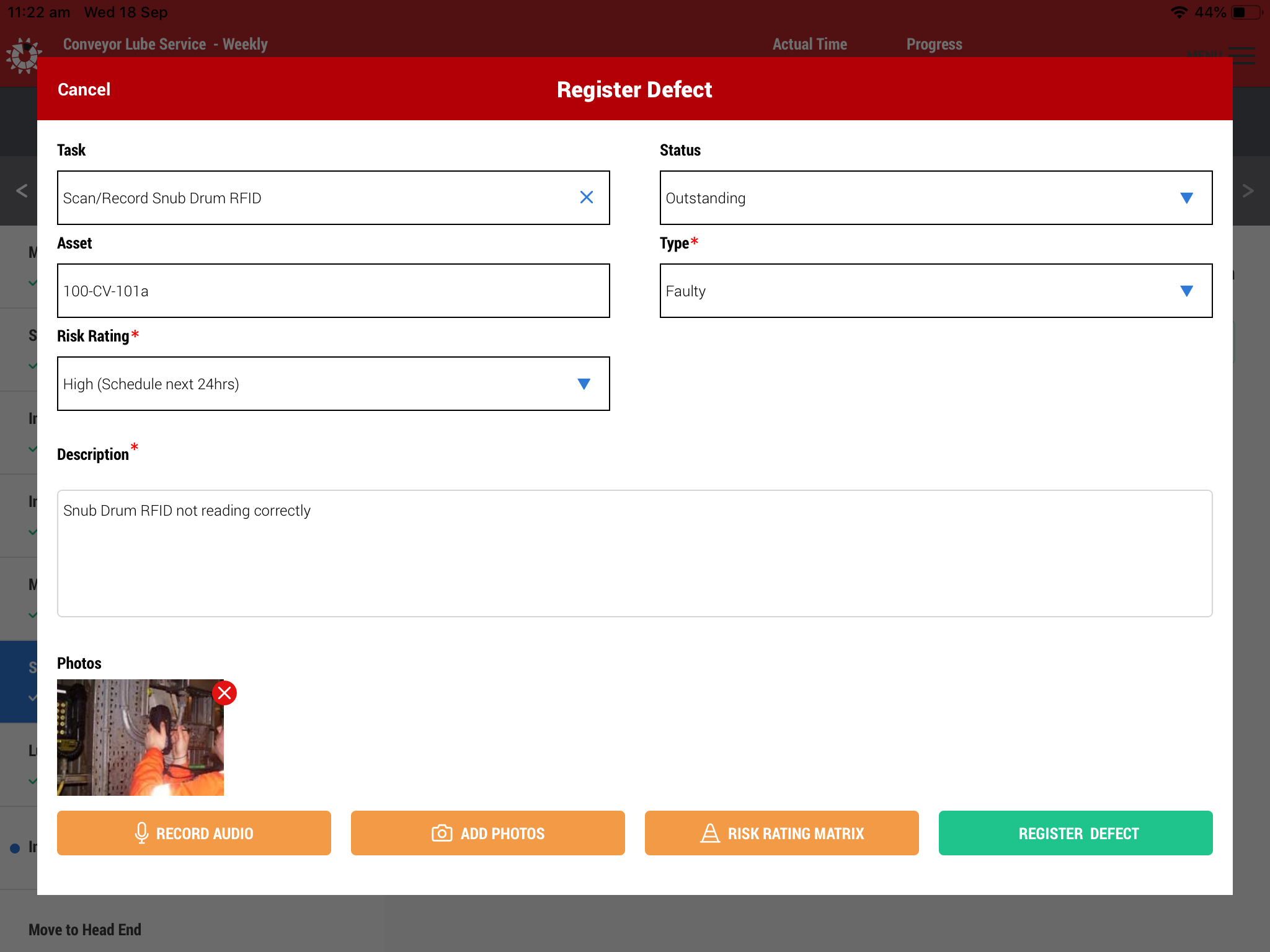

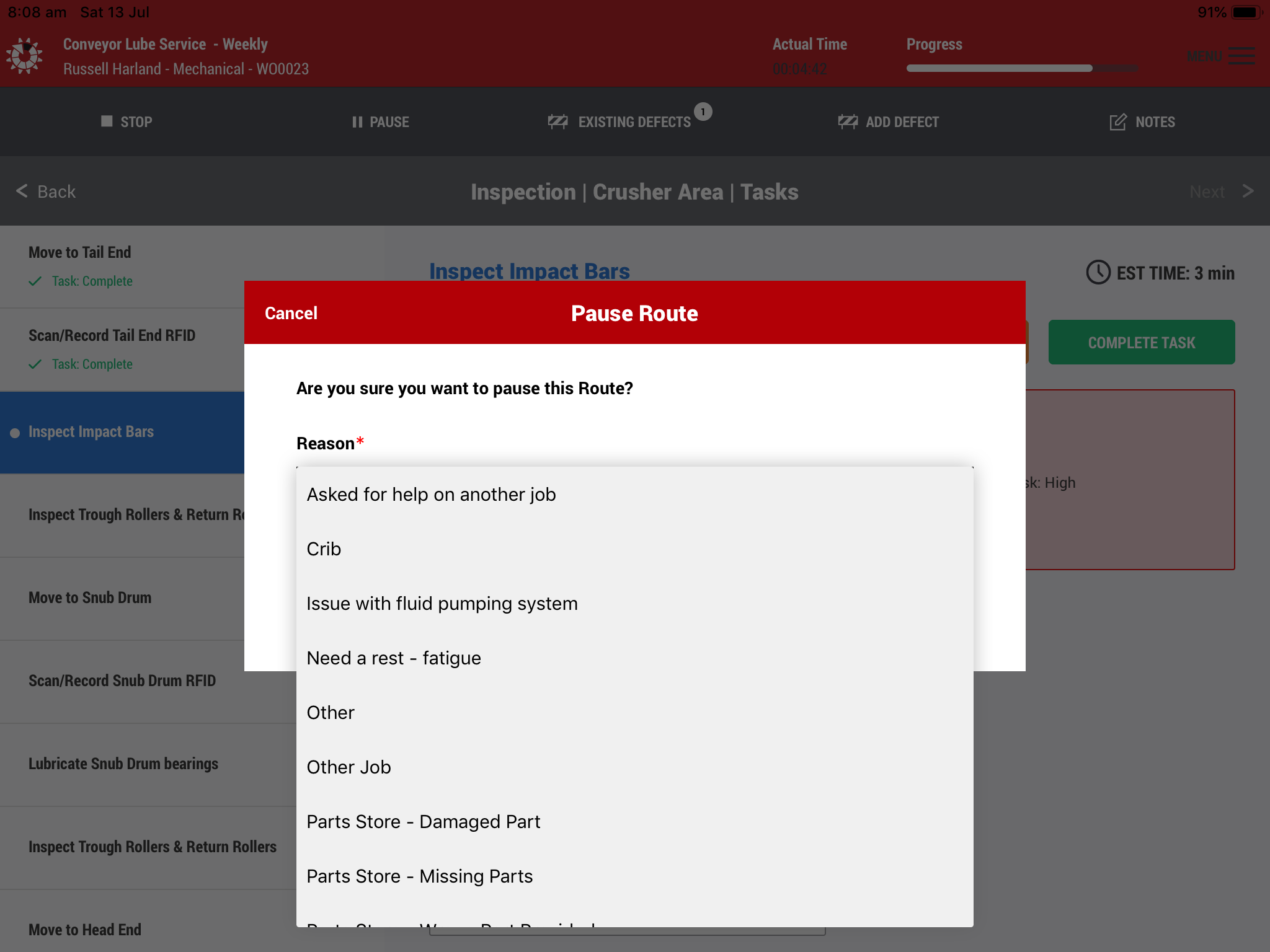

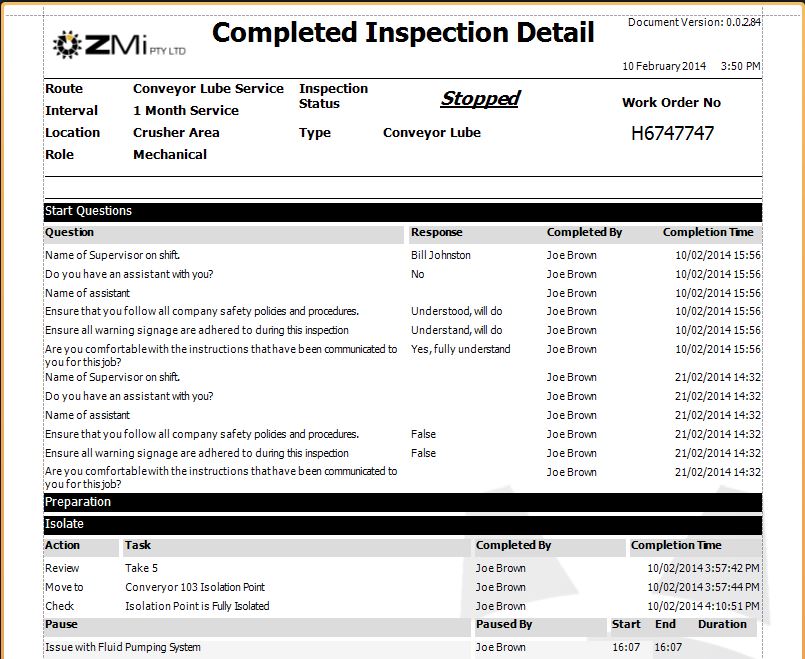

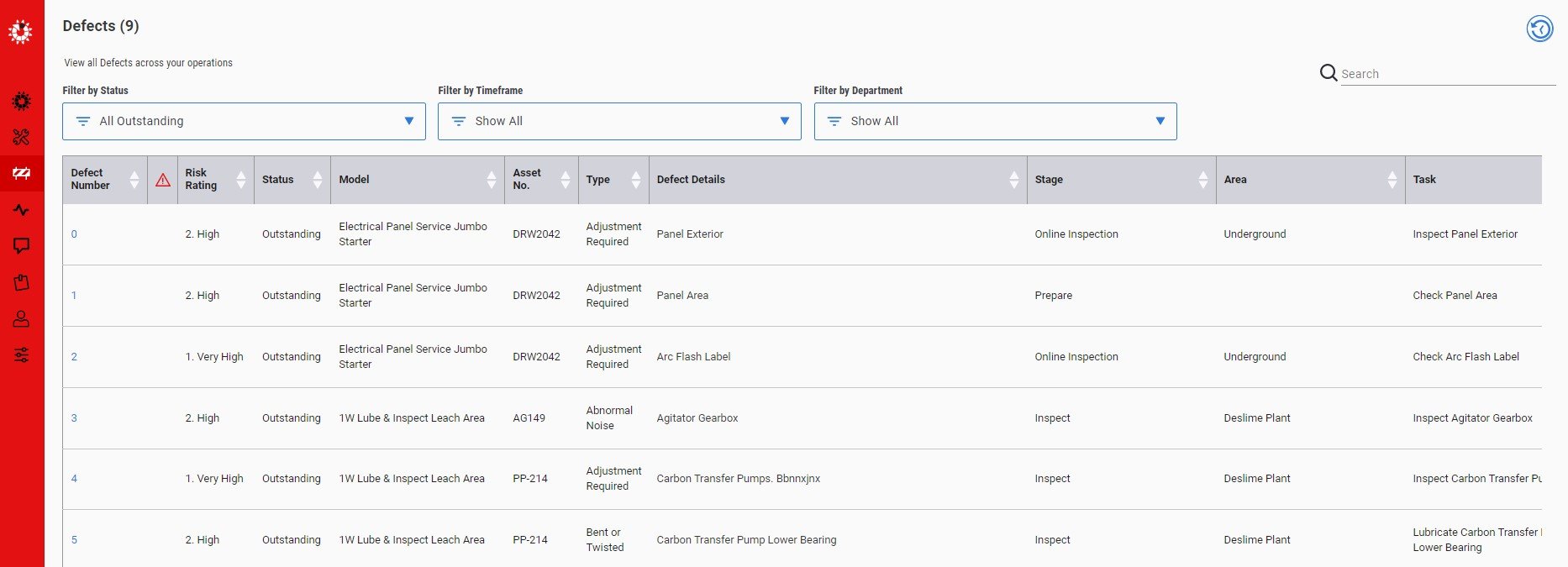

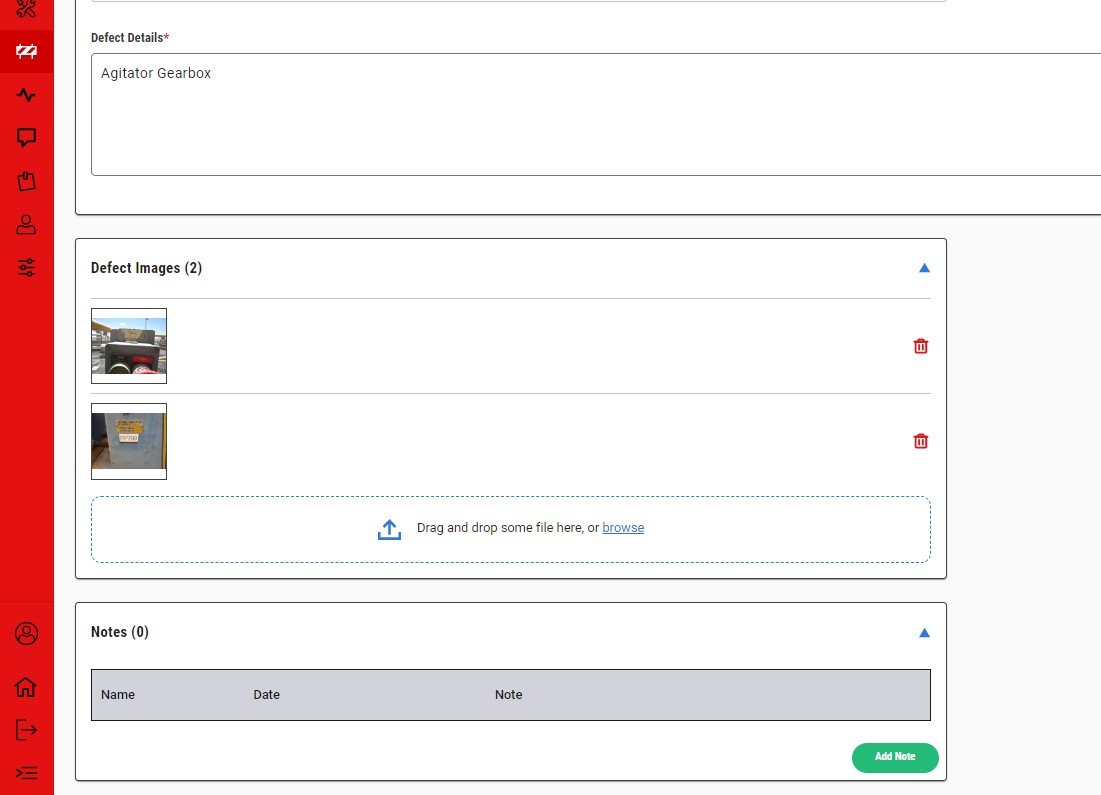

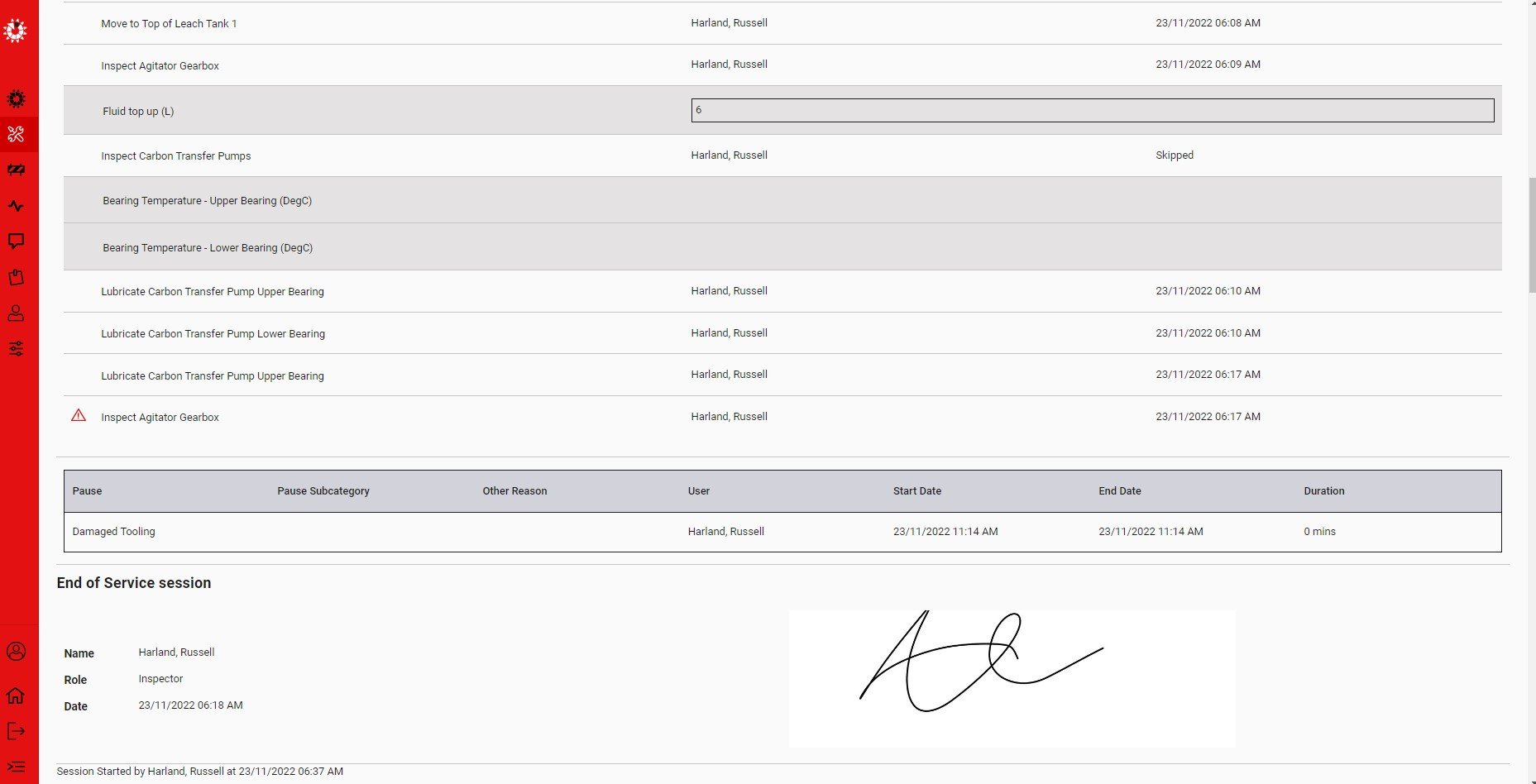

When a technician spots a defect, it can be recorded electronically, risk-rated for future repair priority, and images of the defect can be captured.

This means any previously reported or outstanding defects can easily be viewed, edited, and the asset’s status updated.

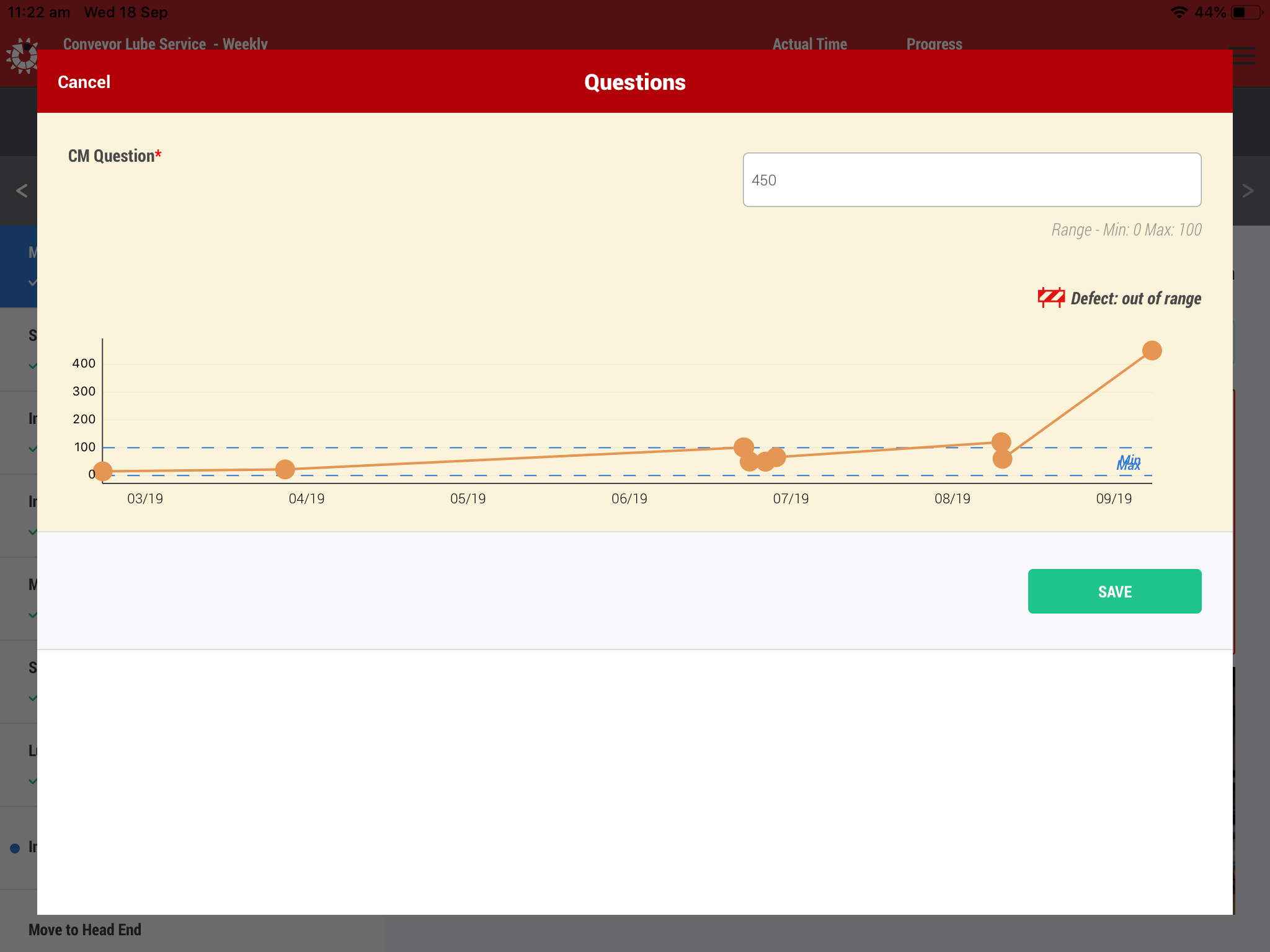

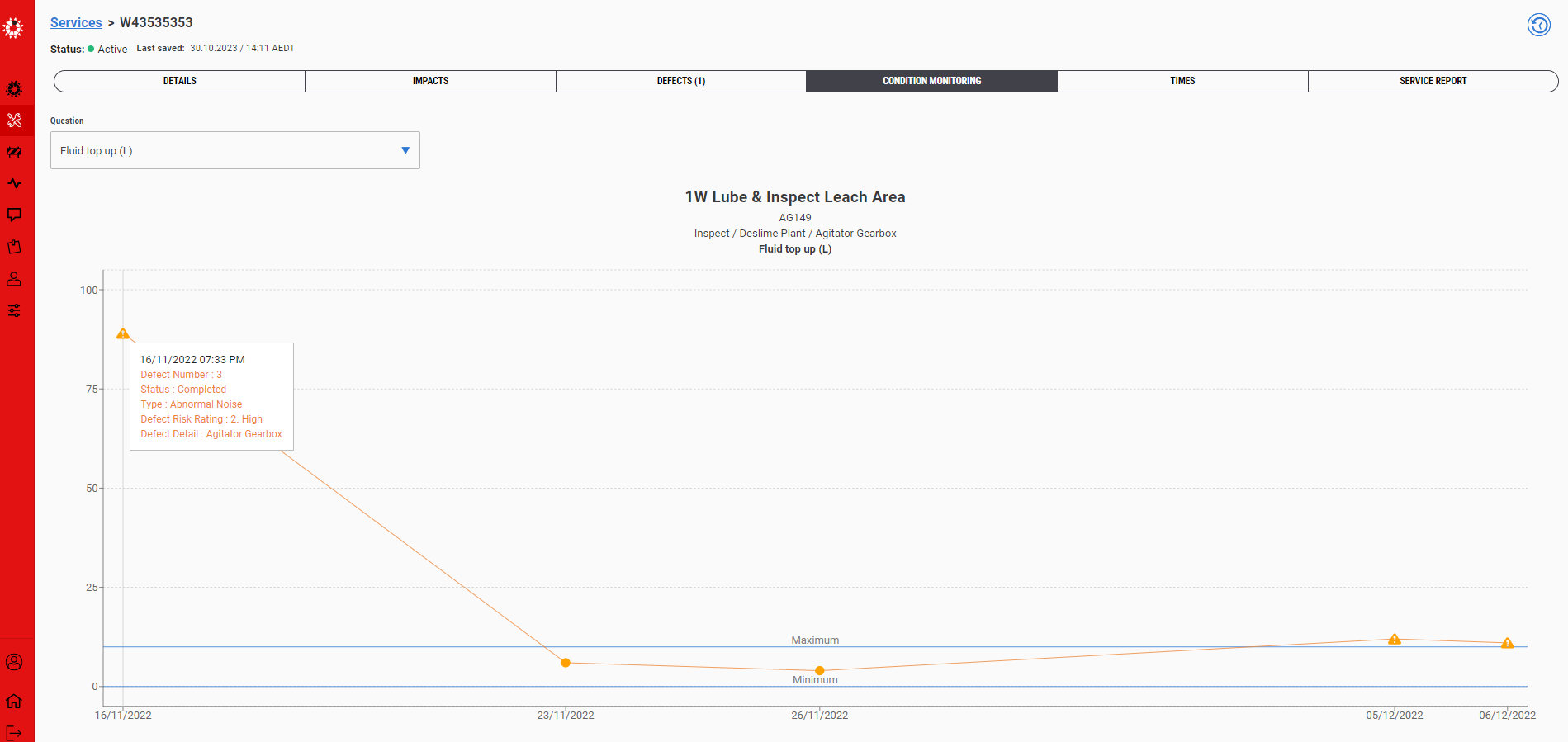

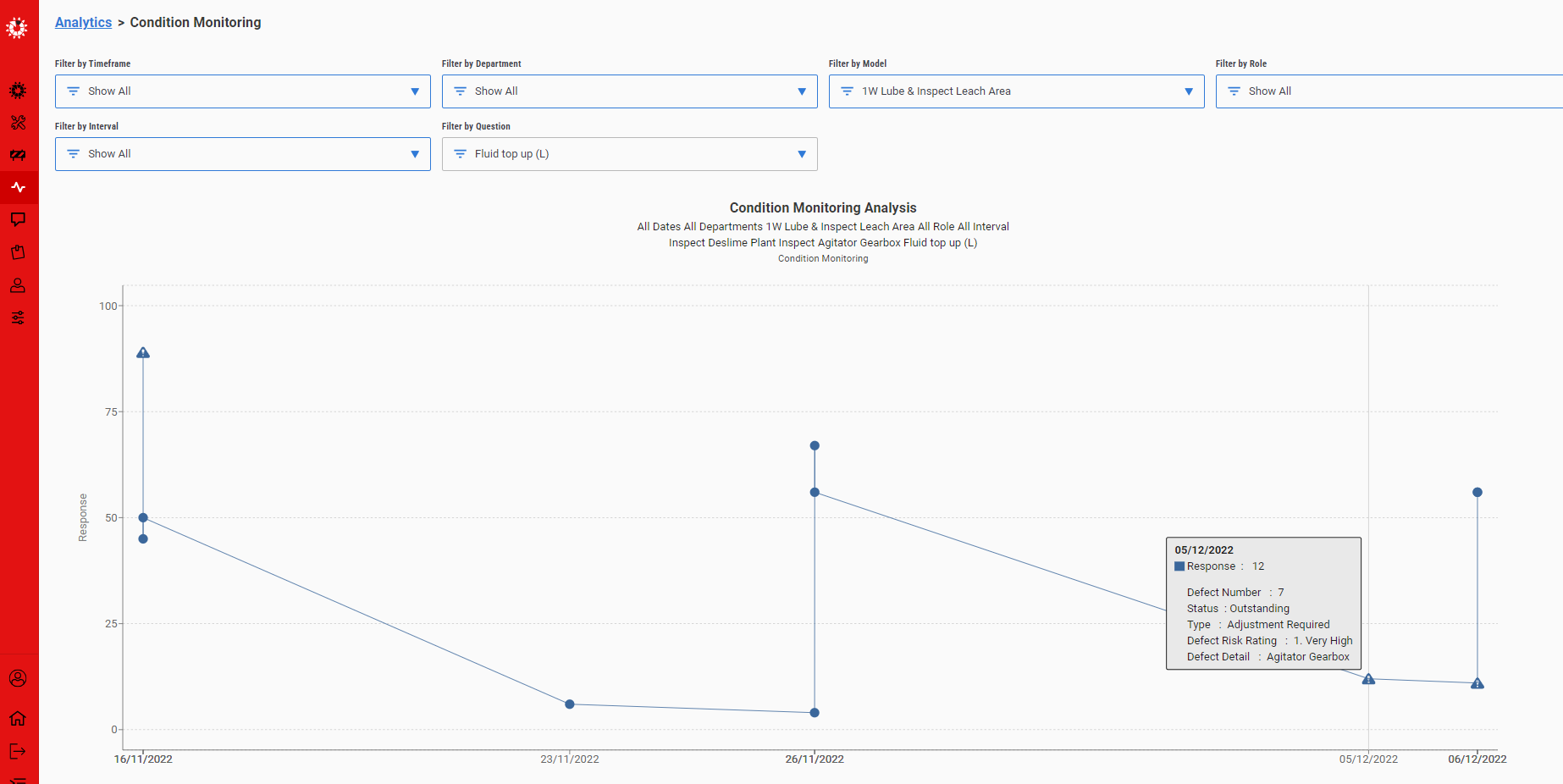

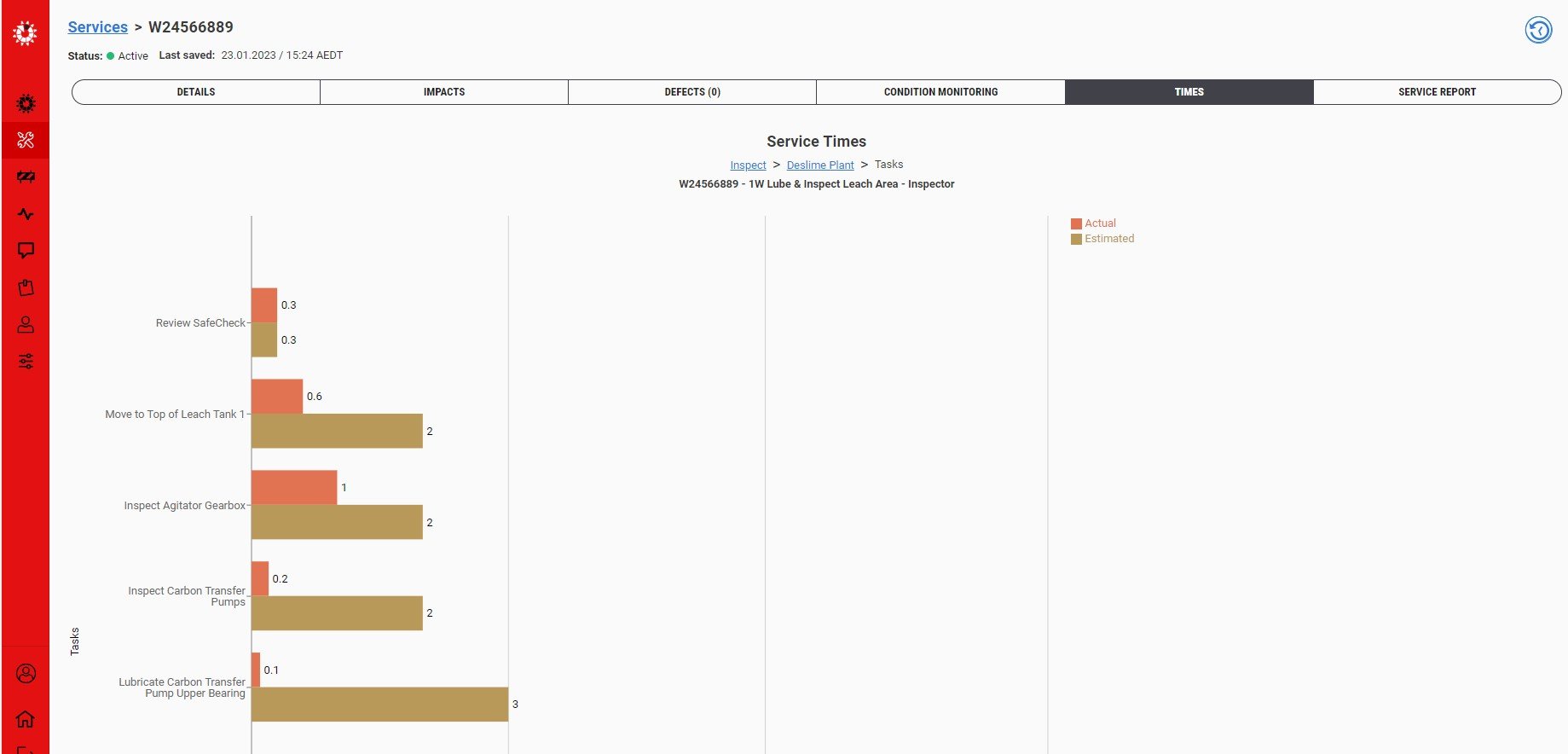

Plus, technical questions are used as prompts to determine the actual condition of a component. Any values that fall outside the min/max range automatically trigger the defect reporting process.

RouteMaintenance also includes our powerful Sensory-Based Data<Link to page 4> integration.

With specifically designed prompts, technicians can record what they see, hear, smell, and touch, which - together with the typical sensor feedback data - helps determine the overall physical condition of the plant in near real-time.

RouteMaintenance addresses many fixed plant issues

When it comes to fixed plant maintenance, we’ve discovered that many mining sites struggle with similar issues.

Do any of these common site problems sound familiar?

Poor skill levels and competencies

Poor quality repairs and servicing practices

Poor defect identification & management practices

Poor data collection methods and management

Poor turnaround times of inspections, lubrication checks

Poor customer (operations) relationships

Poor presentation of end product (servicing and repairs)

Poor process controls and management. No repeatable practices between shifts and individuals

Poor resource management

Poor identification of skills required for the task

Poor planning and scheduling methods and management

Poor condition monitoring analysis – access and acquisition of suitable data

Poor safety standards at task level

Poor availability of information at task level

Poor understanding of task purpose or procedures

Over servicing and under servicing of equipment/plant

Loss of knowledge through high staff turn over

High maintenance and management costs

Poor asset reliability and availability

Lack of standards and set expectations

Lack of focus on reducing waste

Lack of change management successes

Lack of standard practices between multiple sites within the same organisation

Poor inventory control

Poor systems in place. Systems driving the process and decisions rather than process driving the system and decisions

The good news, all these issues can be addressed with RouteMaintenance.

Eliminate paper-based packs with software designed for in-field inspections and plant maintenance tasks

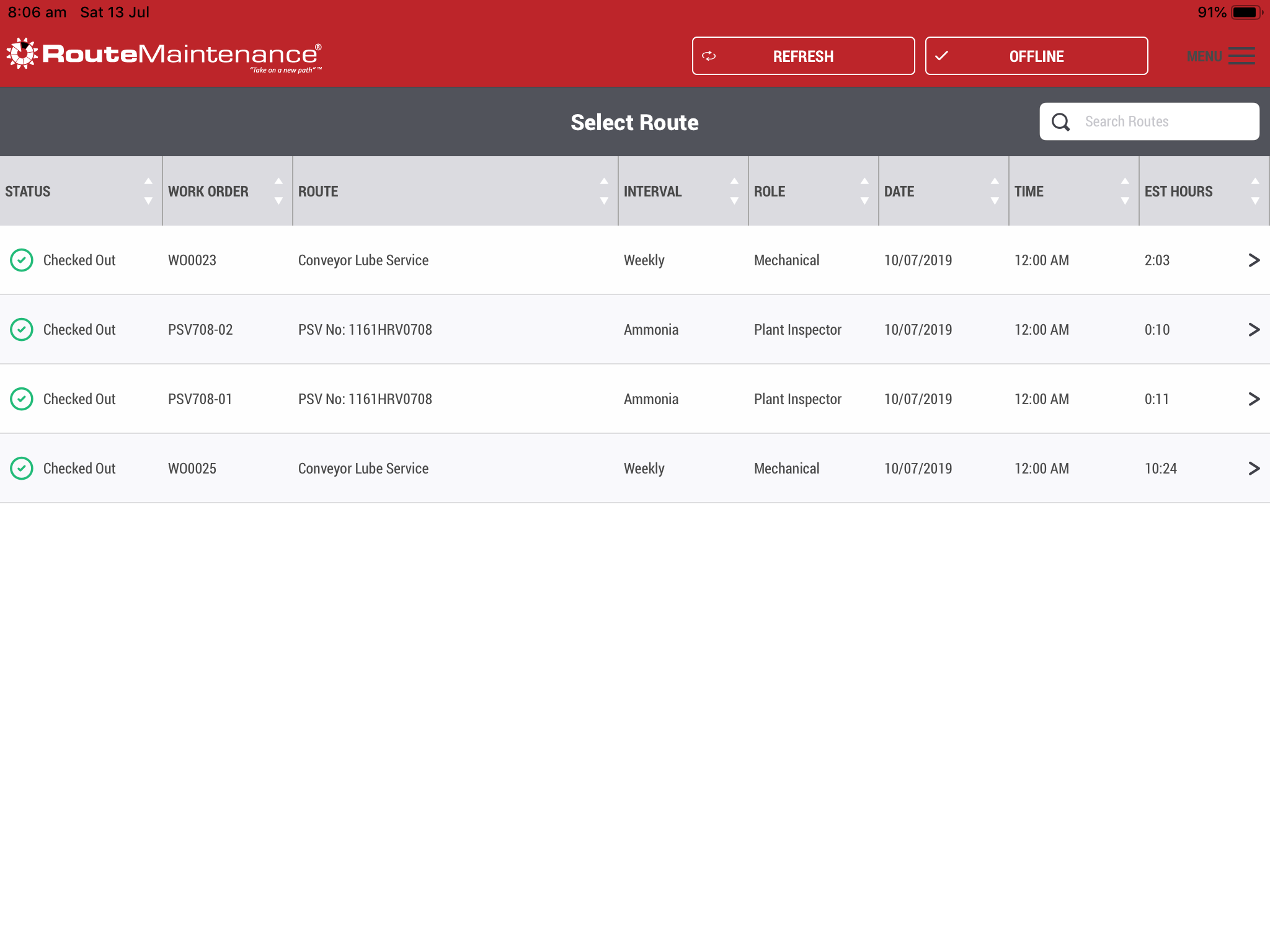

A route is a defined path specific to a list of inspection tasks that need to be checked at regular intervals.

Generally, routes have already been developed in a paper format. Inspection intervals have already been set up, and maintenance teams carry out the processes in some form.

But it’s often not very productive. And information sharing is far from efficient.

RouteMaintenance is our advanced application that offers your maintenance team the necessary information electronically at the time of each defined task.

In fact, the amount of routes you can develop is limitless.

Even more importantly, our software has been developed with the needs of those doing the job and managing the information in mind. We’re not redeveloping or duplicating your existing Computer Maintenance Management System (CMMS) but advancing it.

Plus, RouteMaintenance could be integrated seamlessly with your CMMS (for example, SAP).

Want to eliminate paper-based inspection sheets and wasted servicing times?

Creating a simple process that’s repeatable and efficient

Let’s be honest. It should be about consistency, not speed.

When it comes to fixed plant maintenance, what’s important is having a process that can be repeated, time and again, autonomously and always to the same level of accuracy.

RouteMaintenance is designed to eliminate wasted time and effort within the scheduled servicing process and inspections of any fixed plant.

Plus, it’s simple to implement in plants of any size.

““Software designed specifically for in the field audits and inspections. Eliminating paper based work packs”.”

New iPad Software

Amazing new screens and improved user experience, the iPad software is changing the way maintenance is being executed in fixed plant maintenance

What can you expect with RouteMaintenance?

Results are entirely dependent on your needs and business requirements.

In our experience, substantial site results don’t come about from big changes. They happen because the management team is committed to long term improvements, and they effectively support the evolution of simple workplace habits.

If your company:

needs to make a serious adjustment to improve,

this need outweighs any potential resistance to change,

and the change will benefit all levels of your workforce,

Then it’s entirely possible to quickly achieve 30-40% improvements across your combined servicing timeframes.

We work closely with your team and communicate with all levels.

We take the time to explain what can be achieved and what the system and process are about.

The thing that sets RouteMaintenance apart is its ability to blend with your site environment and requirements seamlessly. It’s more than just a flexible software system - it becomes a methodology and defined process for effective execution.

Looking for a better system for your plant maintenance?

Try our demo version.

Routemaintenance analysis software

Other solutions in our Maintenance suite

Streamline your maintenance processes for mobile equipment when safety, quality, and efficient turnaround is essential.