ZoneMaintenance Software

Advanced and flexible mobile mining equipment maintenance software

A Simple Repeatable Process

Do you have declining fleet reliability or long turnaround servicing and repair times?

Or is your maintenance team swamped in paper-based service sheets?

Our powerful and innovative software options improve efficiency and safety - no matter the level of employee experience.

ZoneMaintenance electronically sets out for a technician what needs to be done, when, and how. It also details what’s required in the way of tools, lubricant, parts and permits, so nothing is missed.

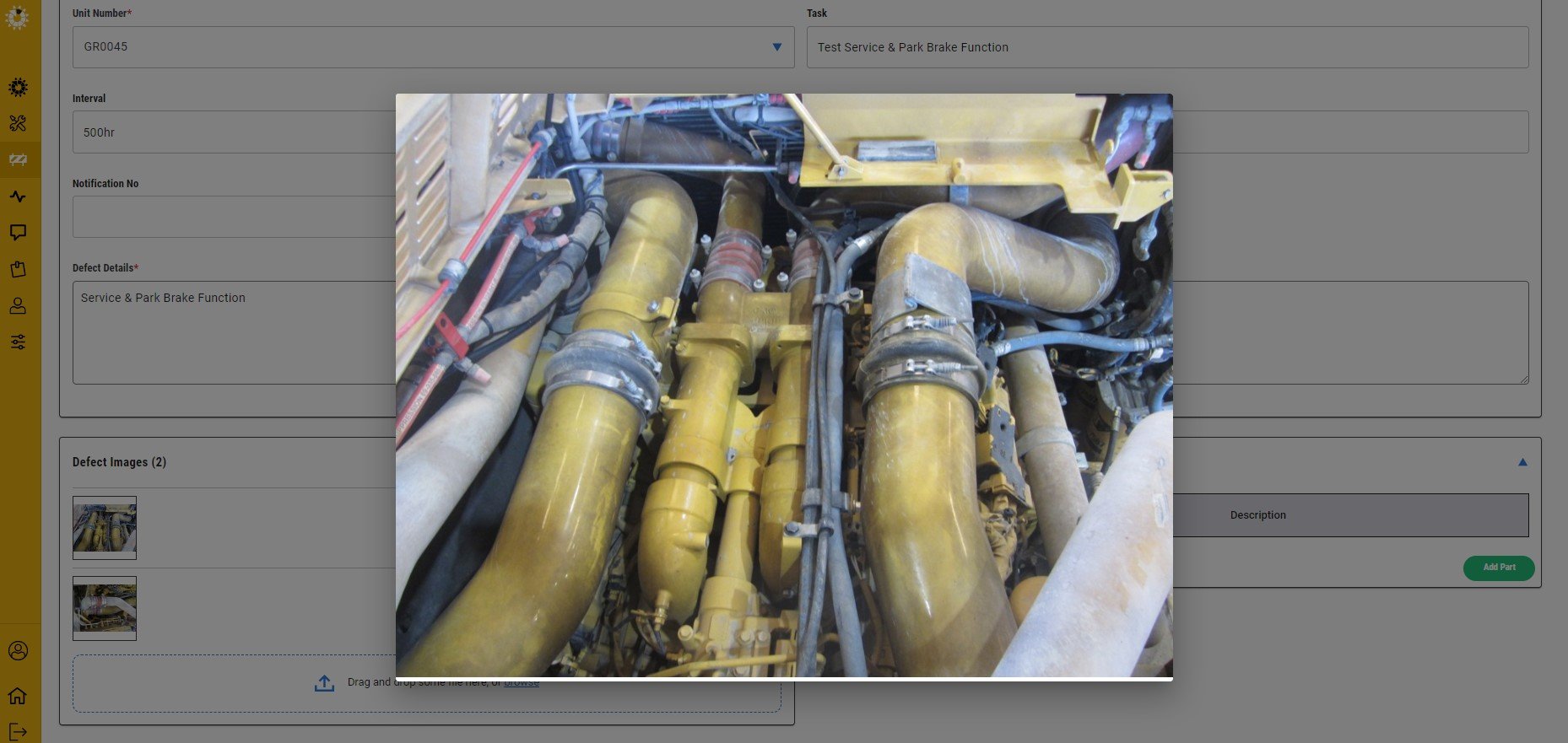

Images, videos and PDFs can also be used to support the steps of each task. And the system clearly identifies any risks involved and when contamination control needs to be applied.

But we take it much further than just digital instructions

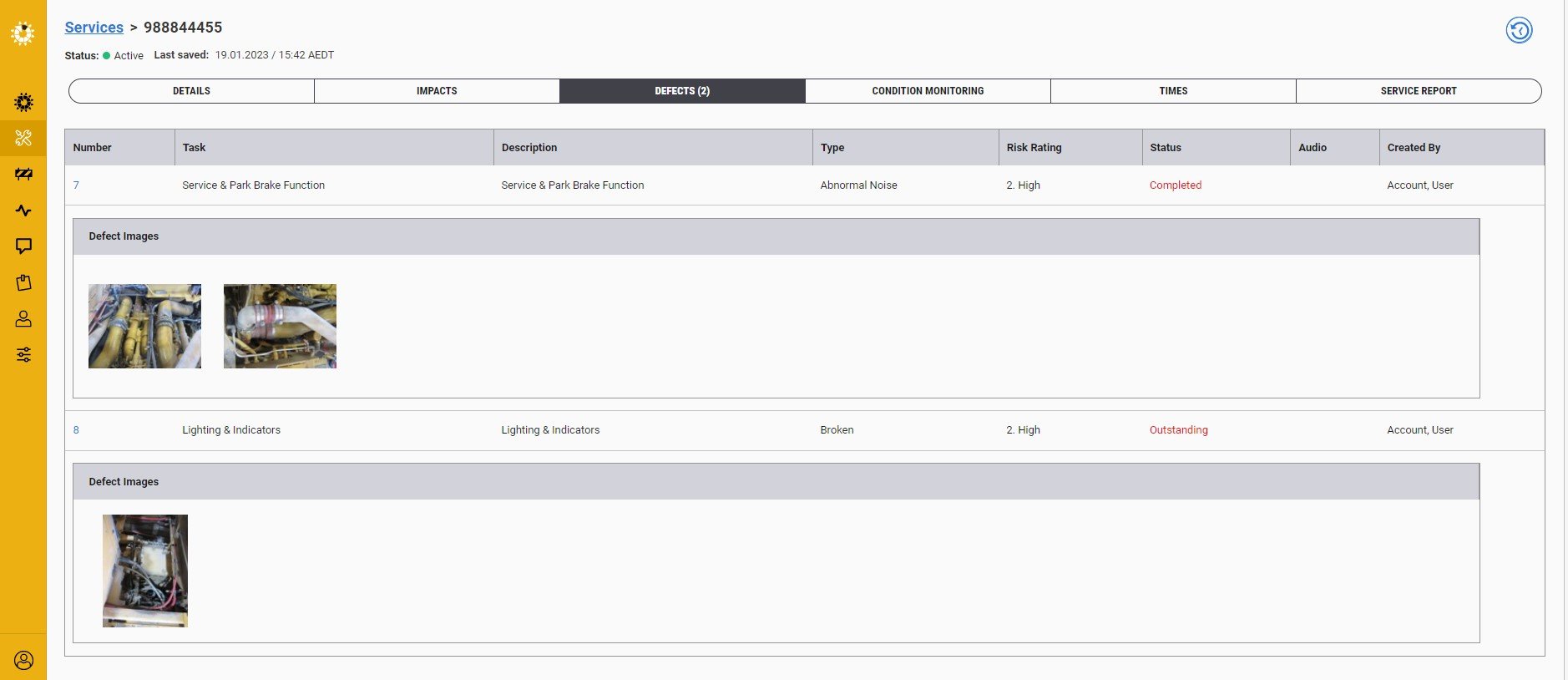

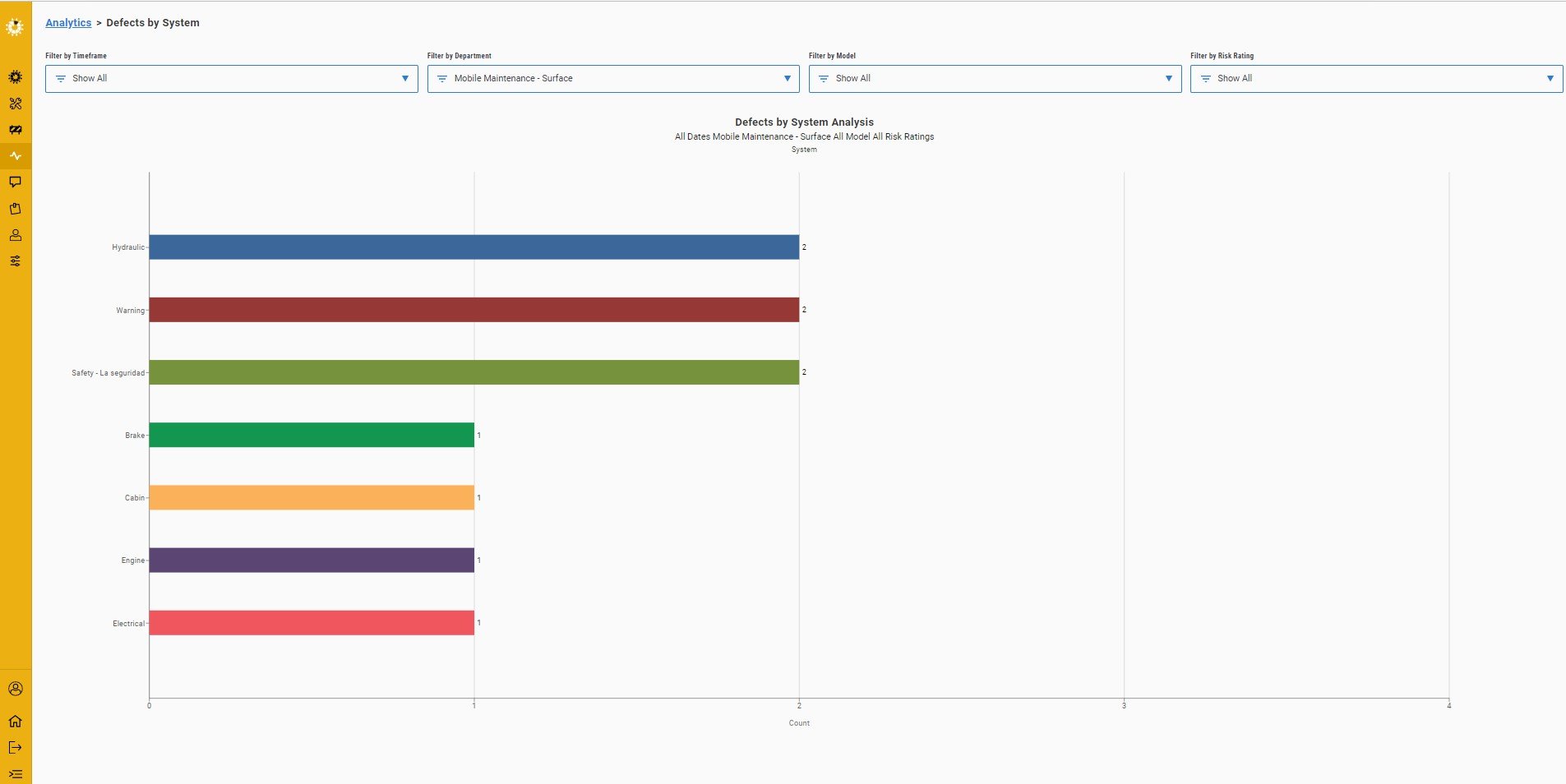

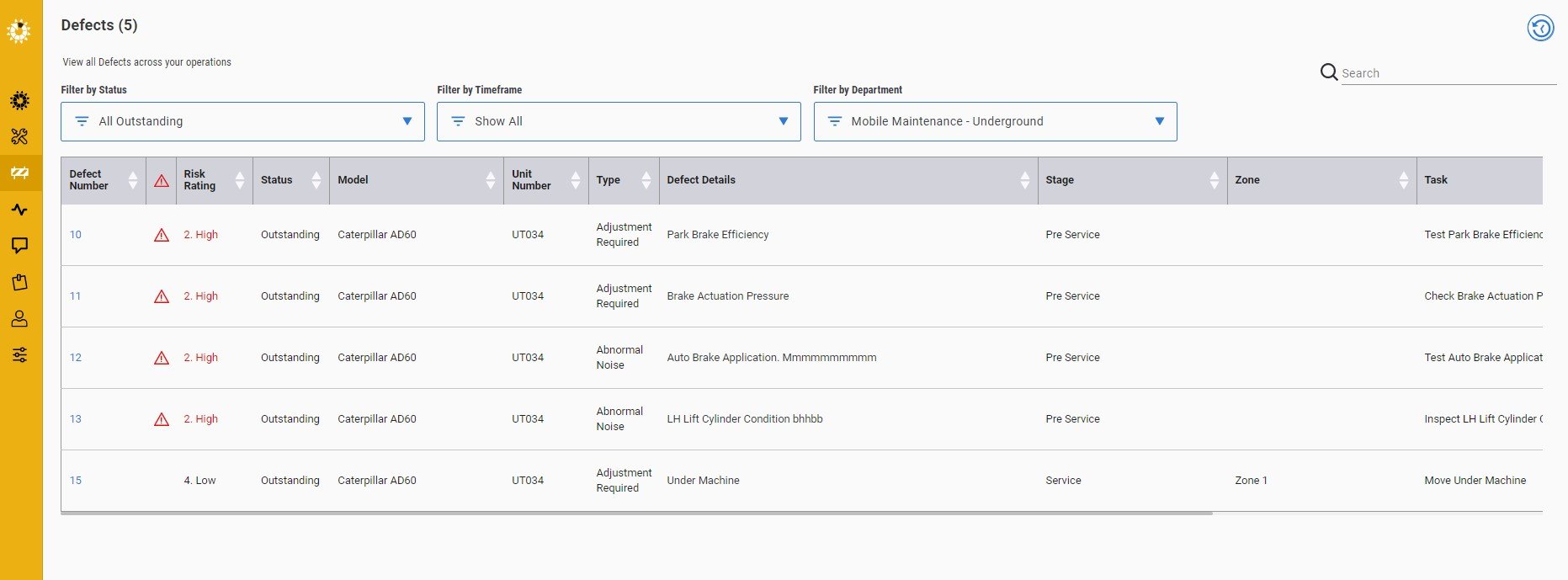

When a technician spots a defect, it can be recorded electronically, risk-rated for future repair priority, and images of the defect can be captured.

This means any previously reported or outstanding defects can easily be viewed, edited, and the asset’s status updated.

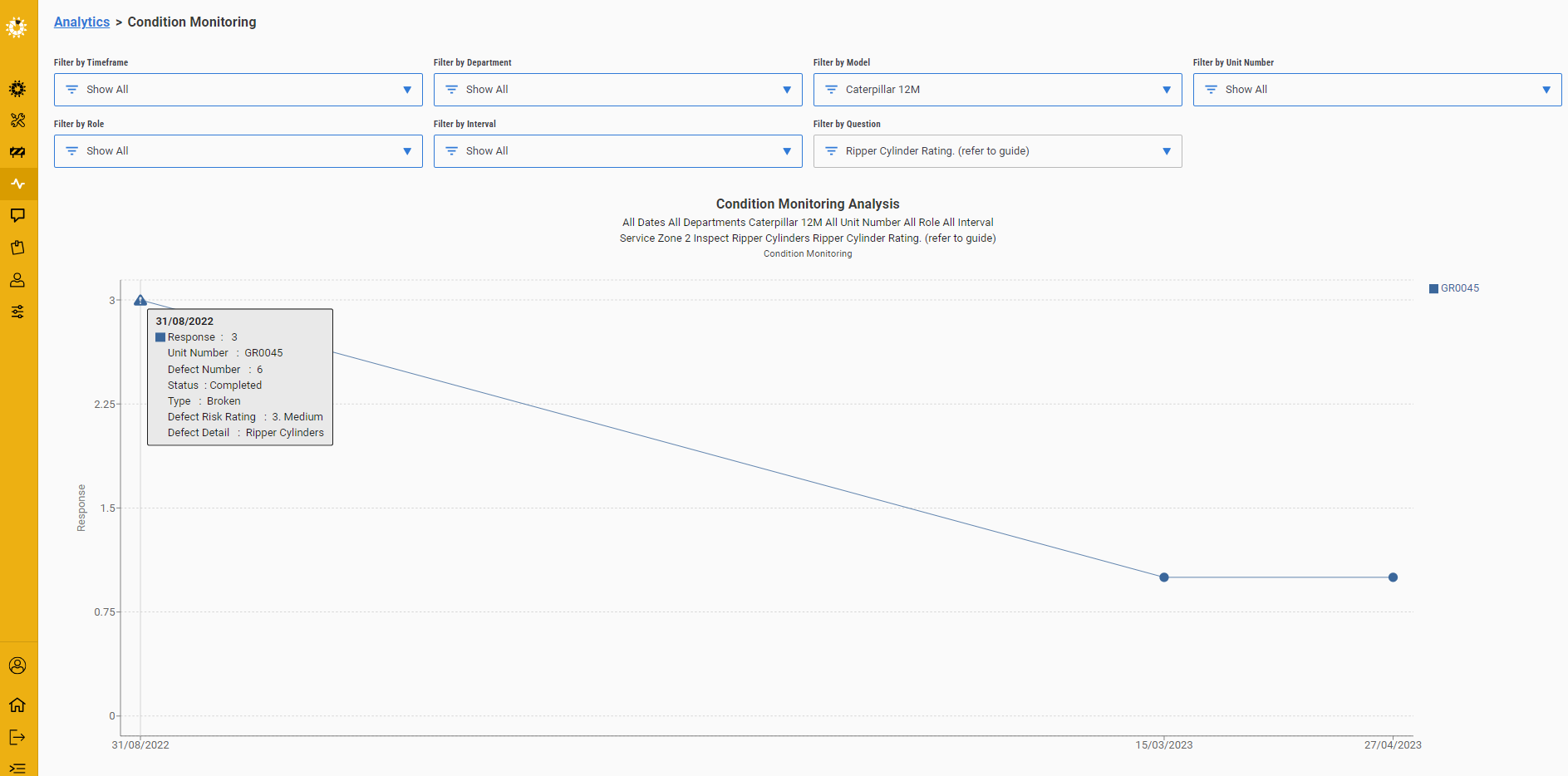

Plus, technical questions are used as prompts to determine the actual condition of the mobile equipment. Any values that fall outside the min/max range automatically trigger the defect reporting process.

ZoneMaintenance also includes our powerful Sensory-Based Data integration.

With specifically designed prompts, technicians can record what they see, hear, smell, and touch, which - together with the typical sensor feedback data - helps determine the physical condition and overall health of the asset in near real-time.

With principles that are simple to adopt and manage, ZoneMaintenance is user-friendly and designed to work with your workforce in mind.

ZoneMaintenance addresses many mobile plant issues

Research shows that many mining sites struggle with similar issues, particularly when it comes to mobile plant maintenance.

Do any of these common site problems sound familiar?

Poor skill levels and competencies

Poor quality repairs and servicing practices

Poor defect identification & management practices

Poor data collection methods and management

Poor turnaround times of refuelling, servicing and repairs

Poor customer (operations) relationships

Poor presentation of end product (servicing and repairs)

Poor process controls and management. No repeatable practices between shifts and individuals

Poor resource management

Poor identification of skills required for the task

Poor planning and scheduling methods and management

Poor condition monitoring analysis – access and acquisition of suitable data

Poor safety standards at task level

Poor availability of information at task level

Poor understanding of task purpose or procedures

Over servicing and under servicing of equipment

Loss of knowledge through high staff turn over

High maintenance and management costs

Poor equipment reliability and availability

Lack of standards and set expectations

Lack of focus on reducing waste

Lack of change management successes

Lack of standard practices between multiple sites within the same organisation

Poor inventory control

Poor systems in place. Systems driving the process and decisions rather than process driving the system and decisions

The good news, all these issues can be addressed with ZoneMaintenance.

““Our maintenance software and methods are designed to eliminate wasted time and effort within Preventative Maintenance (PM) Services has reduced servicing time > 30% and reduced unplanned breakdowns by > 40%.

We provide a defined process to performing effective, repeatable servicing and inspections for mobile mining equipment”.”

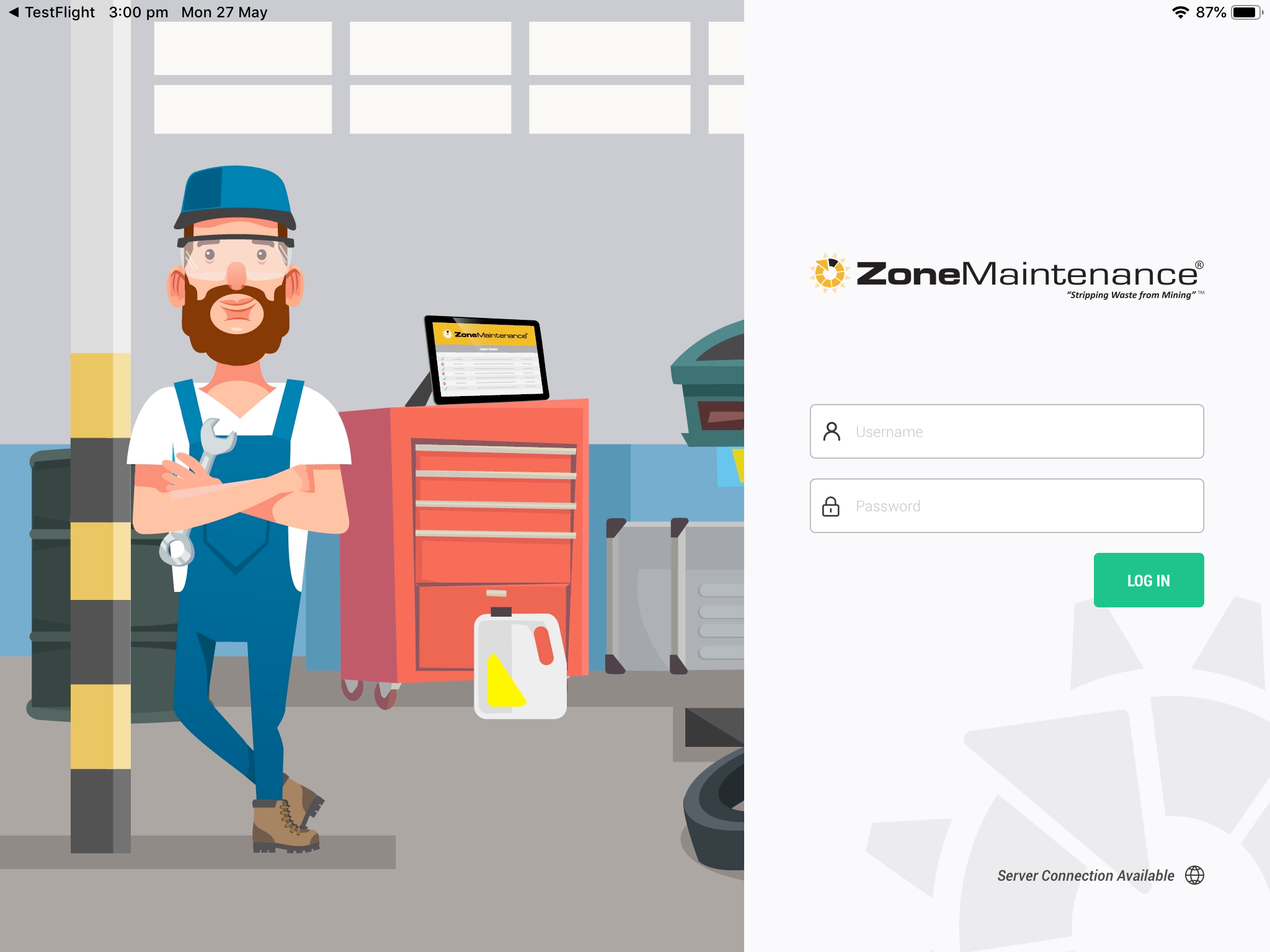

iPad Software

Amazing new screens and improved user experience, the iPad software is changing the way maintenance is being executed

Creating a simple process that’s repeatable and efficient

It should be about consistency, not speed.

When it comes to mining equipment maintenance, what’s important is having a process that can be repeated, time and again, autonomously and always to the same level of accuracy.

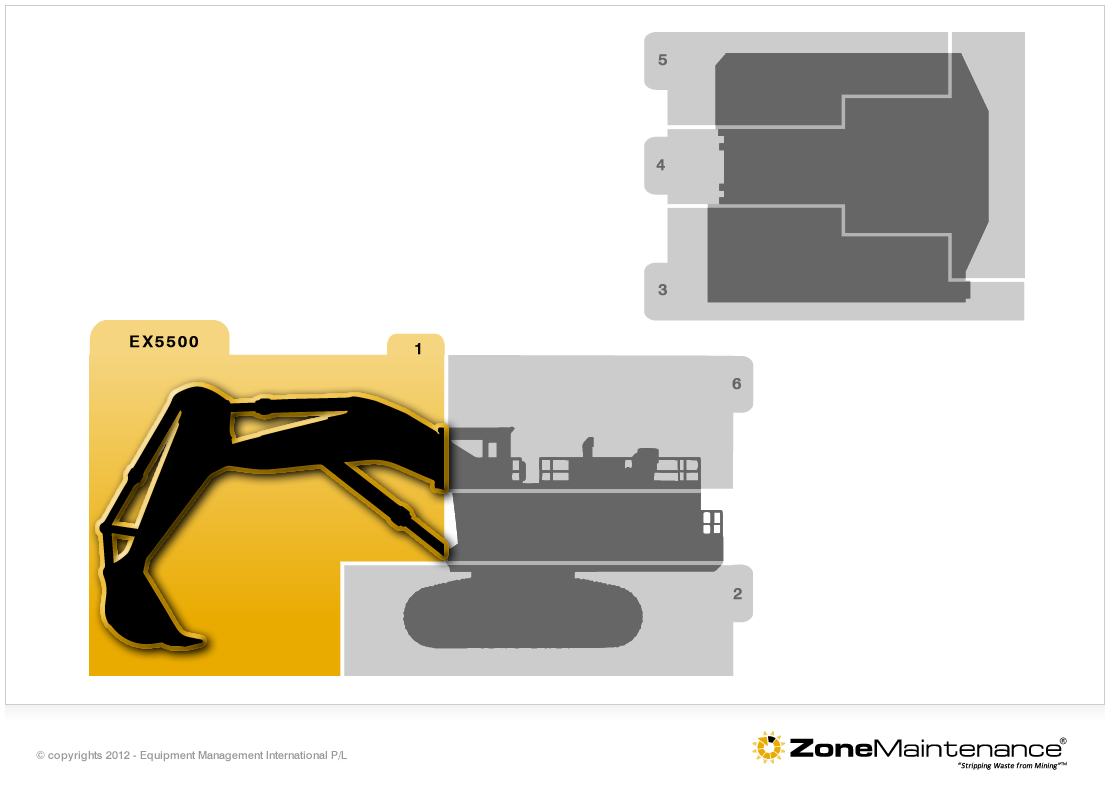

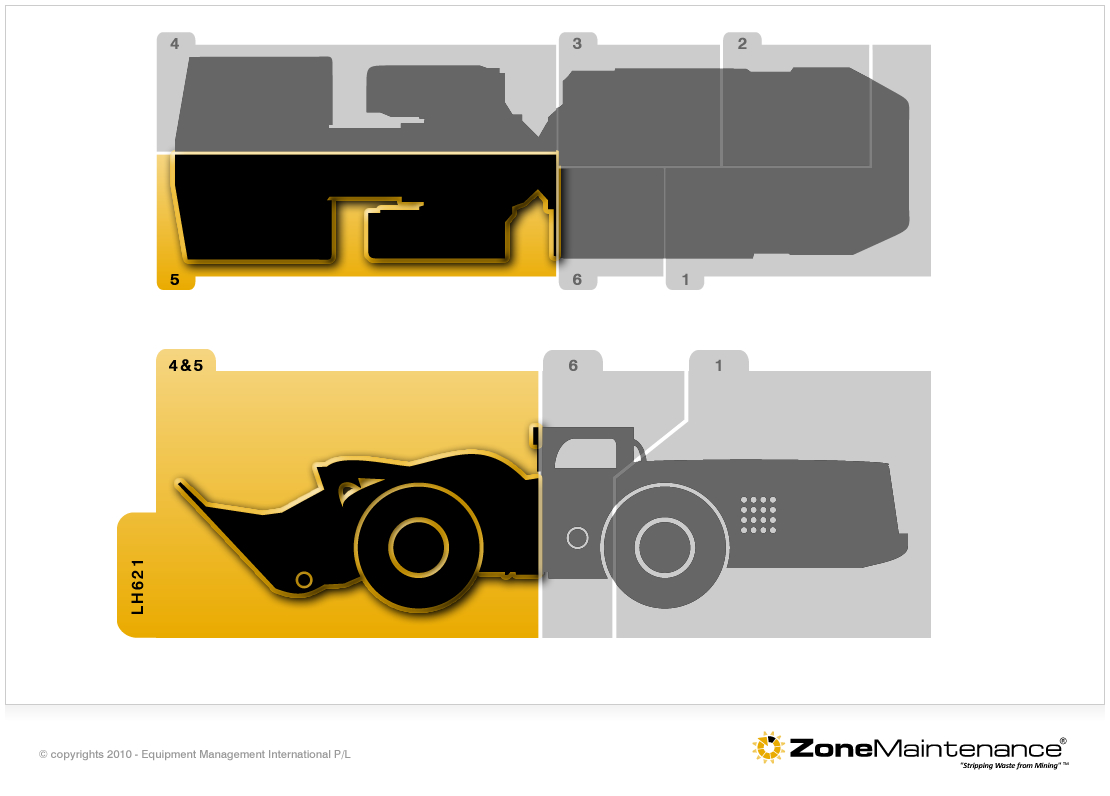

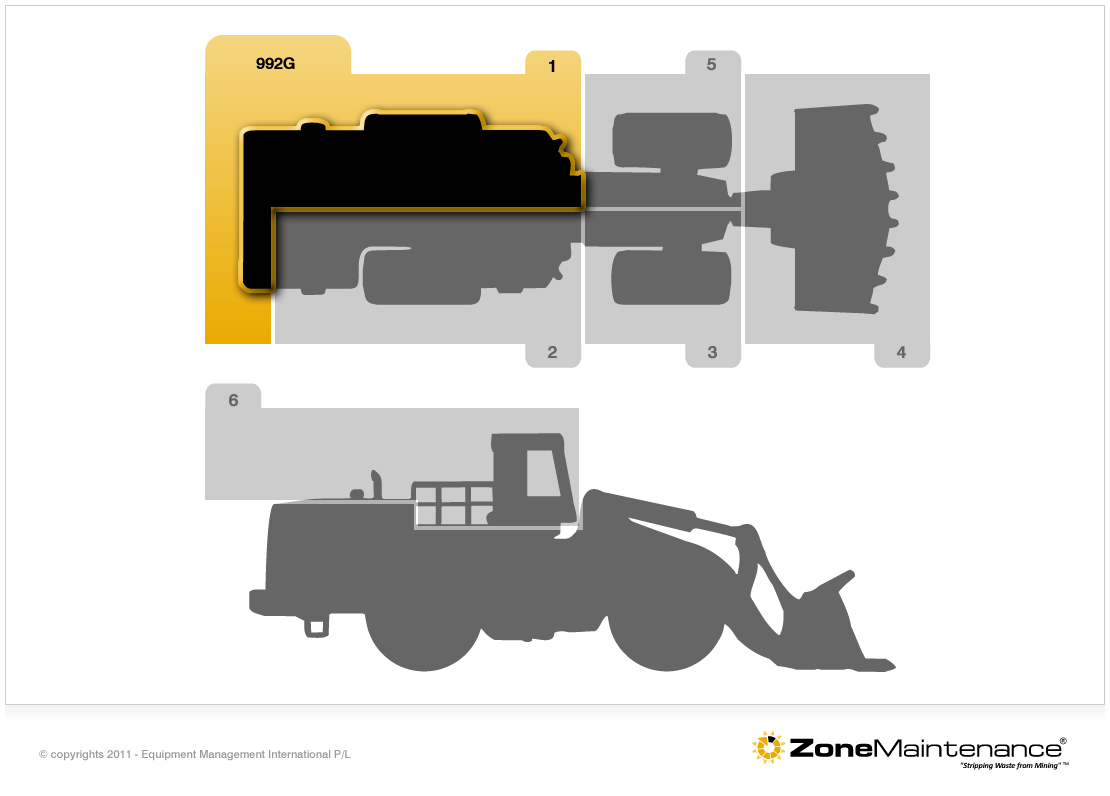

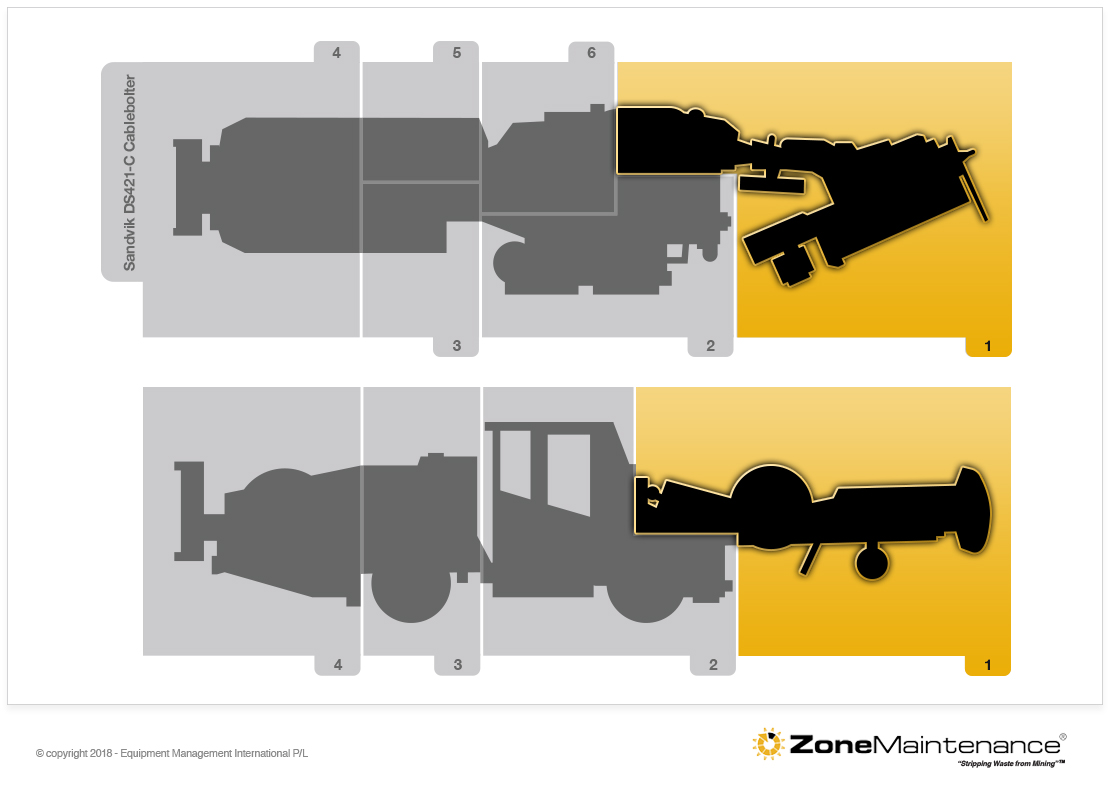

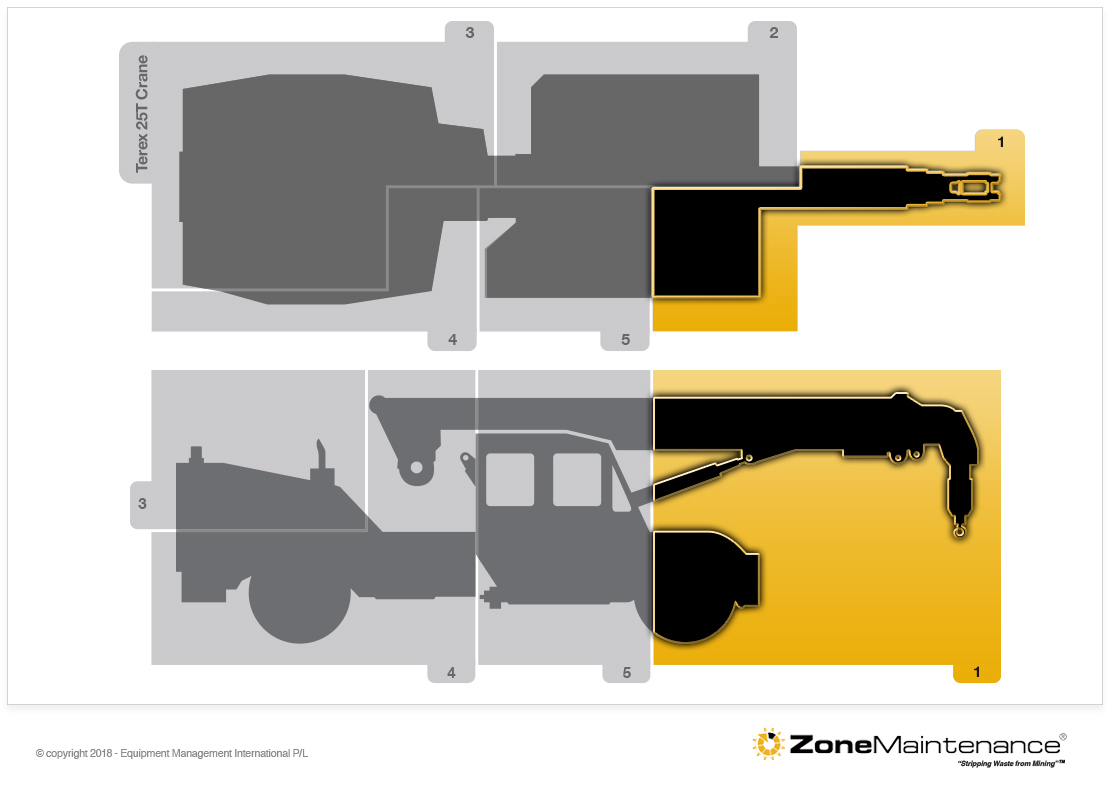

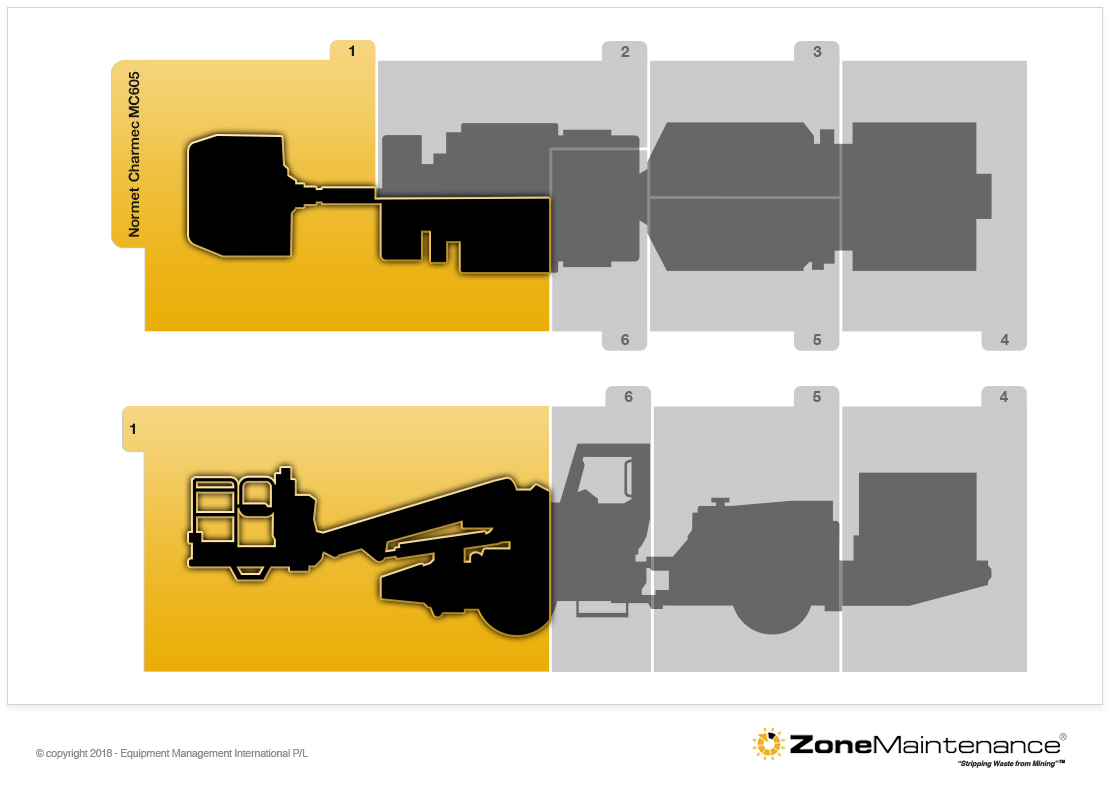

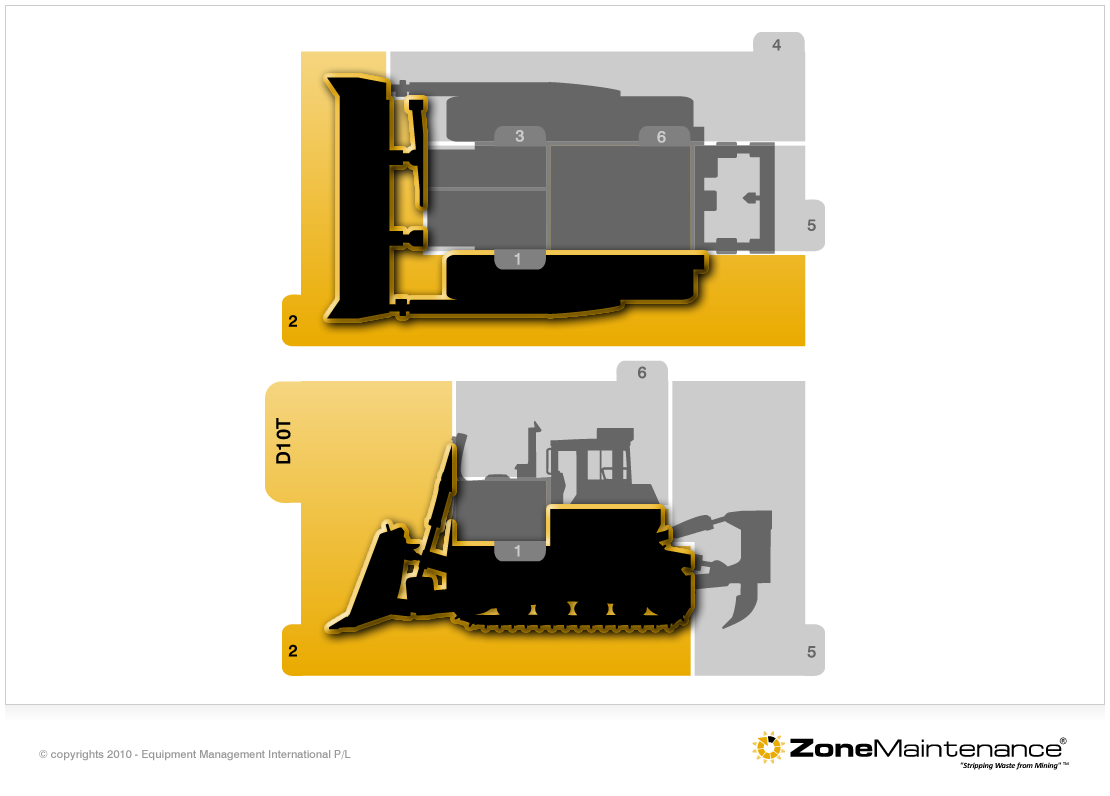

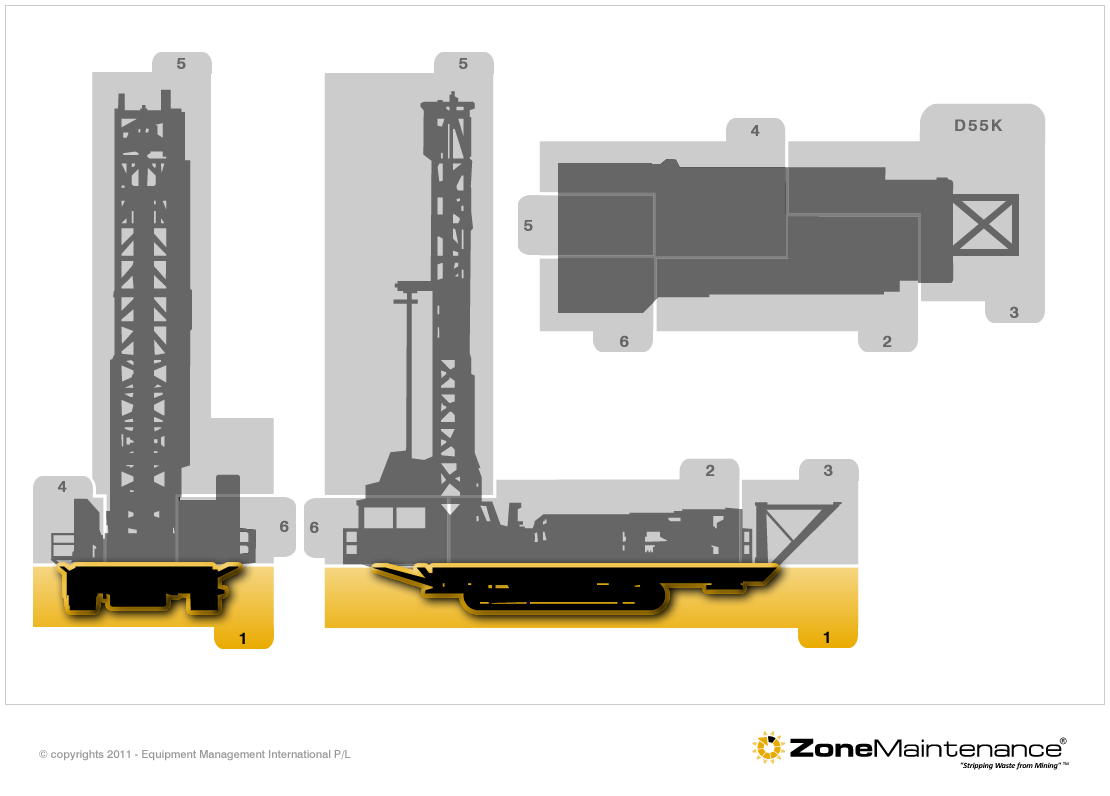

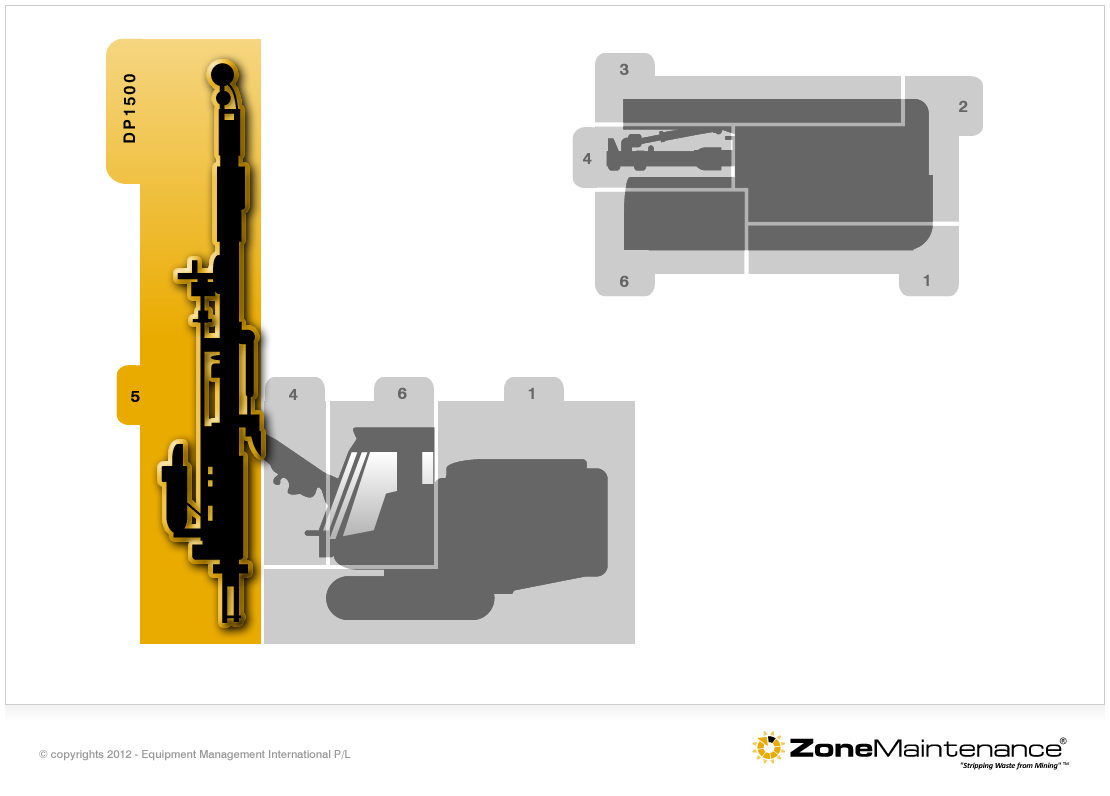

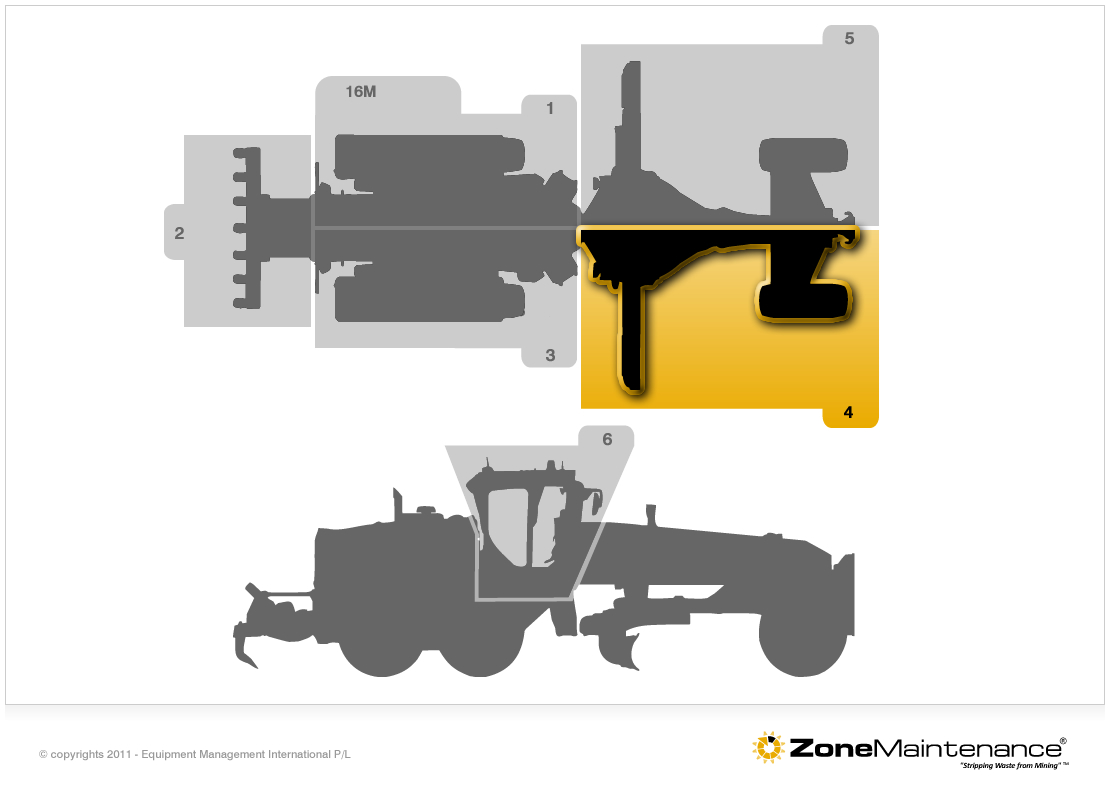

ZoneMaintenance is ideal for mobile assets, such as:

- Off-highway trucks

- Large excavators or face shovels

- Rope shovels

- Motor graders

- Track type and wheel dozers

- Wheel loaders

- Production drills

- Underground trucks and loaders

- Practically any mobile machine

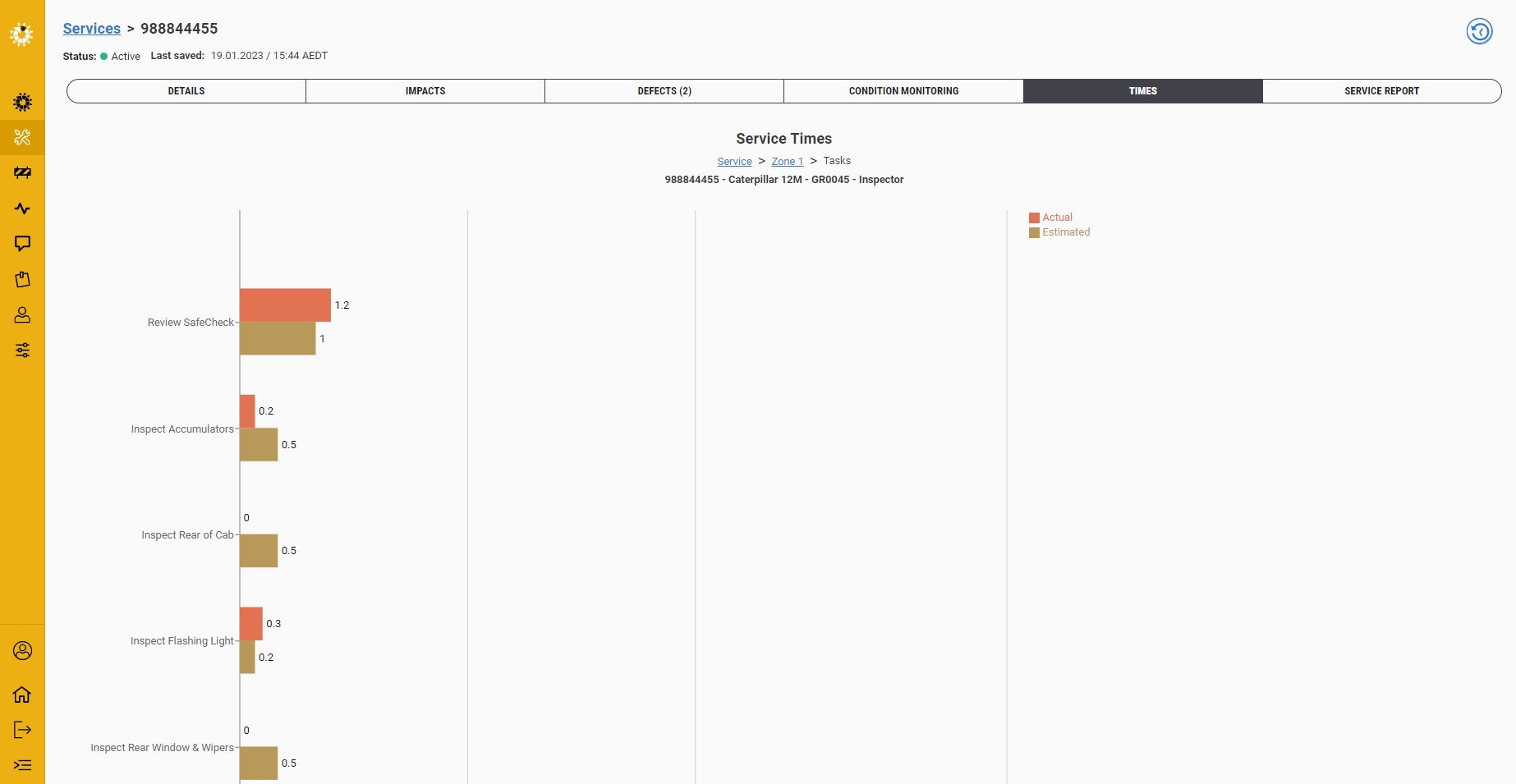

ZoneMaintenance is designed to eliminate wasted time and effort within the scheduled PM servicing process of any mobile plant.

Plus, it’s simple to implement in sites of any size.

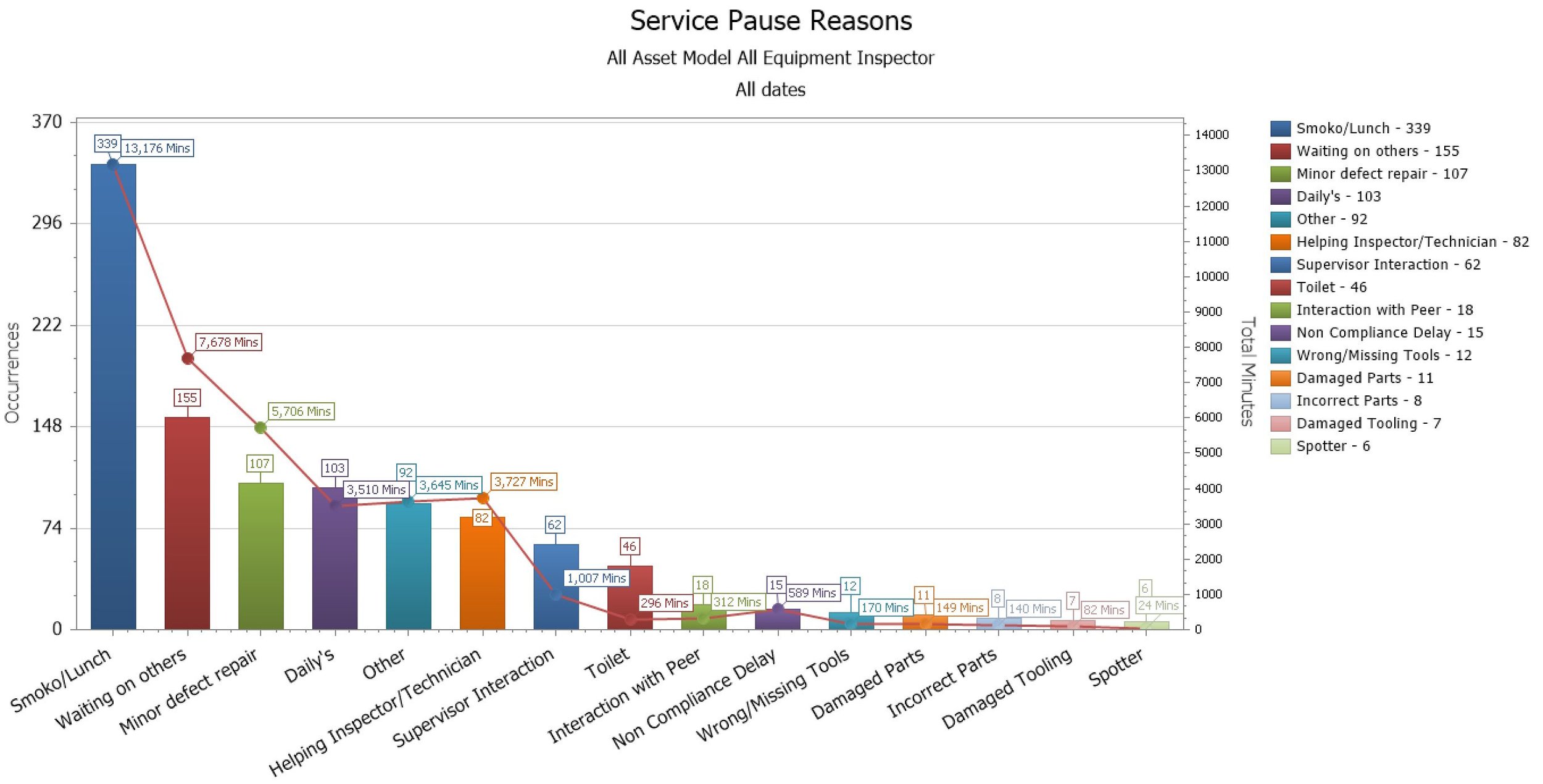

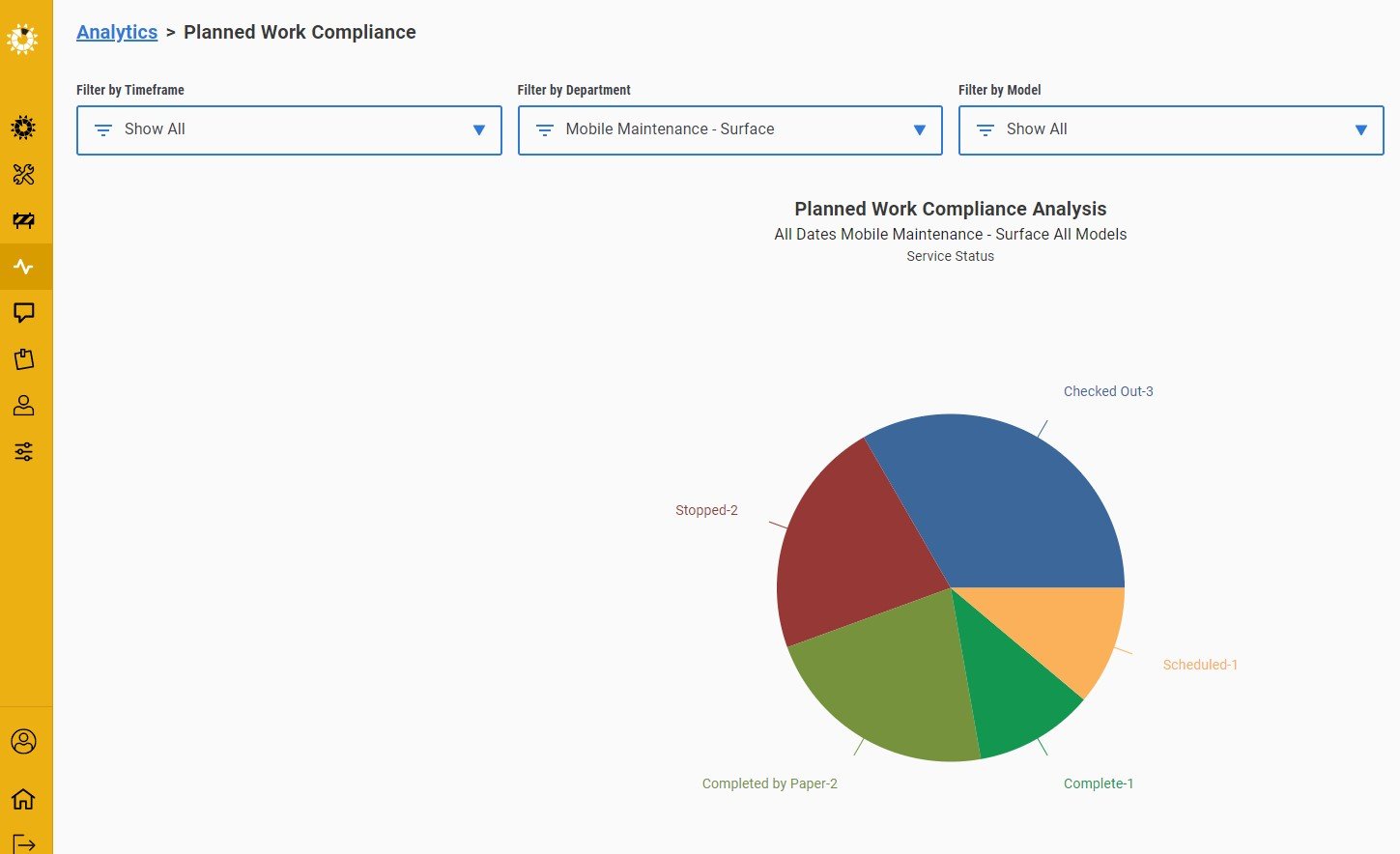

Zonemaintenance analysis software

Our software and methods deliver results that will:

- Save TIME by increasing ‘uptime’

- Save EFFORT by reducing labour costs

- Save MONEY by improving your bottom line

We’ve done the figures, and the results are in

When safety, quality, and effective turnaround is essential, we can help you streamline your maintenance processes for mobile equipment with ZoneMaintenance.

Companies using our software report:

More productivity, with a 30% reduction in PM service times.

Improved fleet reliability, with 40% fewer unplanned breakdowns.

Put ZoneMaintenance to work at your site today.

What can you expect with ZoneMaintenance?

Results are entirely dependent on your needs and business requirements.

In our experience, substantial site results don’t come about from big changes. They happen because the management team is committed to long term improvements and effectively support simple changes to existing workplace habits.

If your company:

needs to make a serious adjustment to improve,

this need outweighs any potential resistance to change,

and the change will benefit all levels of your workforce,

Then it’s entirely possible to quickly achieve 30-40% improvements across your combined servicing timeframes and a step change in asset reliability.

We work closely with your team and communicate with all levels.

We take the time to explain what can be achieved and what the system and process are about.

The thing that sets ZoneMaintenance apart is its ability to blend with your site environment and requirements seamlessly. It’s more than just a flexible software system - it’s a methodology that becomes a defined process in itself.

Looking for a better system for your mining equipment maintenance?

Try our demo version.

Other solutions in our Maintenance suite

Focus on efficient, clearly defined, and repeatable methods for carrying out periodic inspections of fixed plant facilities.